8

ENGLISH

−

Reversing lever fully to the right:

reverse

3.

Set torque only with the reversing

lever in forward position:

−

Reversing lever fully to the left =

maximum torque.

−

Reversing lever one step to the

right = torque is reduced.

−

Adjust working pressure at the

compressor (see Technical spec-

ifications for max. permissible

working pressure).

4.

Connect quick coupler to the air

supply.

5.

Pull trigger to start.

A

Danger!

Always disconnect from air

supply before servicing.

Repair and maintenance work other

than described in this section must

only be carried out by qualified spe-

cialists.

•

Check all screwed connections for

tightness, tighten if necessary.

•

If the tool is not lubricated by a serv-

ice unit or line lubricator, add 3-5

drops pneumatic oil to the air inlet

every 15 minutes of use (constant

operation).

•

Do not store tool unprotected out-

doors or in damp environment.

•

Pneumatic oil 0.5 litre

Special lubricant for air tools, serv-

ice units and line oilers.

Stock-no. 090 100 8540

•

Line oiler R3/8" female

For fitting directly to air tools. Oil

level can always be checked

through sight glass.

Stock-no. 090 105 4592

A

Danger!

Repairs to air tools must be

carried out by qualified specialist

ONLY!

Air tools in need of repair can be send to

the service centre in your country. See

spare parts list for address.

Please attach a description of the fault to

the power tool.

The tool's packaging can be 100 % recy-

cled.

Worn out machines and accessories

contain considerable amounts of valua-

ble raw and plastic materials, which can

be recycled.

These instructions are printed on chlo-

rine-free bleached paper.

5.

Care and maintenance

6.

Available accessories

7.

Repairs

8.

Environmental protection

9.

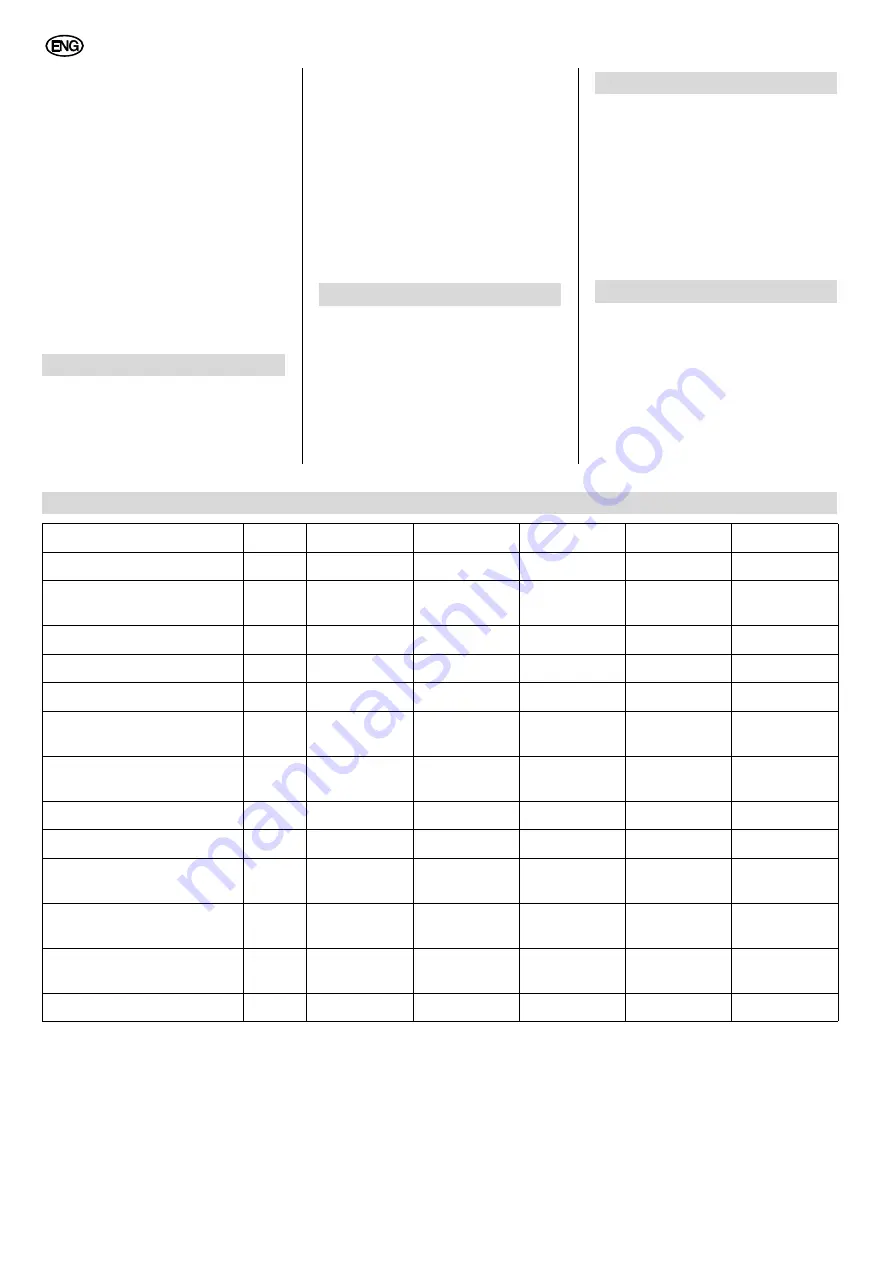

Technical specifications

Model

SR 1500 Set

SR 2700

SR 2900

SR 3500

SR 4500

Air consumption

l/min

400

400

600

600

Max. permissible working pres-

sure

bar

6.3

6.3

6.3

6.3

6.3

Speed min

-1

6500

7500

5500

5500

Square drive

"

1/2

1/2

1/2

3/4

1

Maximum bolt size

M16

M16

M16

M32

M32

Impact mechanism

hammer

jumbo ham-

mer

twin hammer

twin hammer

twin hammer

Maximum torque

(forward)

Nm

3

6

0

6

1

0

67

0

1490

1490

Maximum torque (reverse)

Nm

3

6

0

6

7

0

74

0

1490

1490

Minimum hose size (inner)

mm

10

10

10

13

13

Vibration (effective value of

weighted acceleration)

m/s

2

<2.5

4.52

2.55

3.22

Sound power level L

WA

Sound pressure level L

PA

dB (A)

dB (A)

102

90

104

88

102

87

105

91

Dimensions:

length x width x height

mm

195x70x195

195x70x195

195x70x195

230x97x240

230x97x240

Weight kg

2.3

2.5

2.6

5.7

5.8