KERCOMET 170

and

210, MULTIMIG 150

Brief operating instructions

9

11 Brief operating instructions

A detailed description can be found

in chapter. „Before start up“

Page 10 and chapter. „Start up“

Page 16.

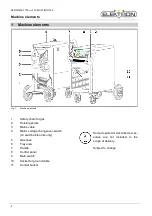

Place the inert gas cylinder on the unit and

secure it with the chain 1.

Remove the screw cap from the inert gas

cylinder and open the valve 32 briefly (blow-

out).

Connect the pressure reducer 13 to the inert

gas cylinder.

Connect the insert gas hose 5 from the unit

to the pressure reducer and open the

cylinder valve.

Insert the mains plug in the socket.

Connect welding return cable to connector

10 and the clamp to the work piece.

Insert wire feed rollers 25 into wire feed unit

in accordance with the type of welding wire

selected, set contact pressure to 2.

Connect the torch to central connector 11

and insert the relevant contact tip to se-

lected welding wire.

Insert welding wire.

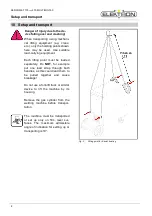

Keep torch switch pressed and set main

switch 9 ON. Magnetic valve will be ac-

tivated!

Adjust gas quantity at pressure reducer.

(Rule: wire diameter x 10 = gas quantity).

Hold down the wire feed switch 29 until the

welding

Wire

projects from the torch neck to

the gas nozzle by approx. 10 mm.

Set required material-wire-gas combination

using characteristic line switch 65.

Select the 2-stroke mode using the button

60.

Select the thickness of material to be

welded using step switch 57.

Torch switch pressed and held = welding.

Release the torch switch = welding process

completed.