- 62 -

moving parts.

If there are devices for connecting dust extraction and

collection facilities, please ensure that they are attached and

used correctly. Using such devices can reduce dust-related

hazards.

Power tool use and care

Do not expect the power tool to do more than it can. Use the

correct power tool for what you want to do. A power tool will

achieve better results and be safer if used in the context for

which it was designed.

Do not use the power tool if the switch cannot turn it on and

off. A power tool with a broken switch is dangerous and must be

repaired.

Disconnect the plug from the power source before making

adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store power tools, when not in use, out of the reach of

children and do not allow people who are not familiar with the

power tool or these instructions to operate it. Power tools are

potentially dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or jammed

moving parts, breakages or any other feature that might affect

the operation of the power tool. If it is damaged, the power tool

must be repaired. Many accidents are caused by using poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to jam and

are easier to control.

Use the power tool, accessories and cutting tools, etc., in

accordance with these instructions and in the manner intended

for the particular type of power tool, taking into account the

working conditions and the work which needs to be done. Using

a power tool in ways for which it was not intended can lead to

potentially hazardous situations.

Service

Your power tool should be serviced by a qualified specialist

using only standard spare parts. This will ensure that it meets

the required safety standards.

Safety instructions for circular saws

for fi rewood

Operation is only allowed with a

safety switch against stray

current (RCD max. stray current

of 30mA).

The machine must be plugged to

400 V with 16 A fuse.

Wear ear protectors. Exposure to noise can cause

hearing loss.

Wear gloves when handling saw blades and rough

materials.

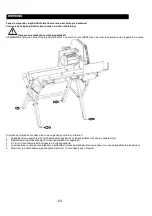

When being operated, the machine must stand on a

horizontal and fl at surface and the fl oor around the

machine must be fl at, well-maintained and with no

waste, such as sawdust and cuttings.

The processed bundle of workpieces and fi nished

workpieces should be placed near the standard place

of work of the operator.

Switch the machine off and unplug it when unattended.

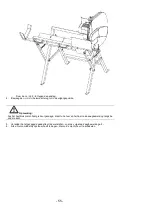

Check all screw and plug-in

connections and protective

equipment if fi rm and tightened

properly and whether all moving

parts are running smooth

whenever the appliance is to be

put into operation

The protective equipment on the

appliance is strictly prohibited to

be disassembled, changed,

used in confl ict with the

designation and it is

prohibited to attach any

protective equipment of

other manufacturers.

The machine must not be used

under any circumstances if the

machine or the safety devices

are damaged.

Before use check machine, cable, and plug for any

damages or material fatigue. Repairs should only be

carried out by authorised Service Agents.

Any faults with the machine, including any related to

the safeguard or the saw blades, must be reported to

the persons in charge of safety as soon as the faults

are discovered.

Before pressing On/Off , make sure the saw blade has

been fi tted properly.

The saw must not be used any longer if the cradle fails

to automatically return to the rest position.

The saw must not be used any longer if the saw

blade fails to stop in 10 seconds after switching the

machine off .

For security, use devices such as safety- and pressure

device, guide slide, rip fence, etc.

Removing sawdust and chippings from the machine

when running is strictly prohibited.

It is necessary to refrain from removing any cuttings

and parts of workpieces from the cutting area.

Do not use saw blades which are damaged or

deformed.

Properly sharpened saw blades to be used only.

Follow instructions for use, adjustment and repair of

saw blades of manufacturers.

Do not use saw blades not corresponding to the key

data given in these instructions for use.

It is essential to adhere to the maximum speed specifi

ed on the saw blade.

Only use tools that meet standard EN 847-1.

Transport and store the tools in a suitable container.

To minimise noise, the tool must be sharpened and

all noise reducing elements (covers etc.) must be

properly adjusted.

Replace the table insert when worn.

Familiarise with the safety procedures for cleaning,

maintenance and regular removal of sawdust and

dust to reduce the risk of fire.

Make sure the fl ange used is suitable for the given

purpose of use, as specifi ed by the manufacturer.

Summary of Contents for 5411074158590

Page 13: ...13 SCH MA DES BRANCHEMENTS...

Page 41: ...41 AANSLUITSCHEMA...

Page 66: ...66 WIRING DIAGRAM...

Page 72: ...72 Procedure 2 1 loosen coach bolt flat washer and locking nut on spring guide tube...

Page 87: ...87...