-5-

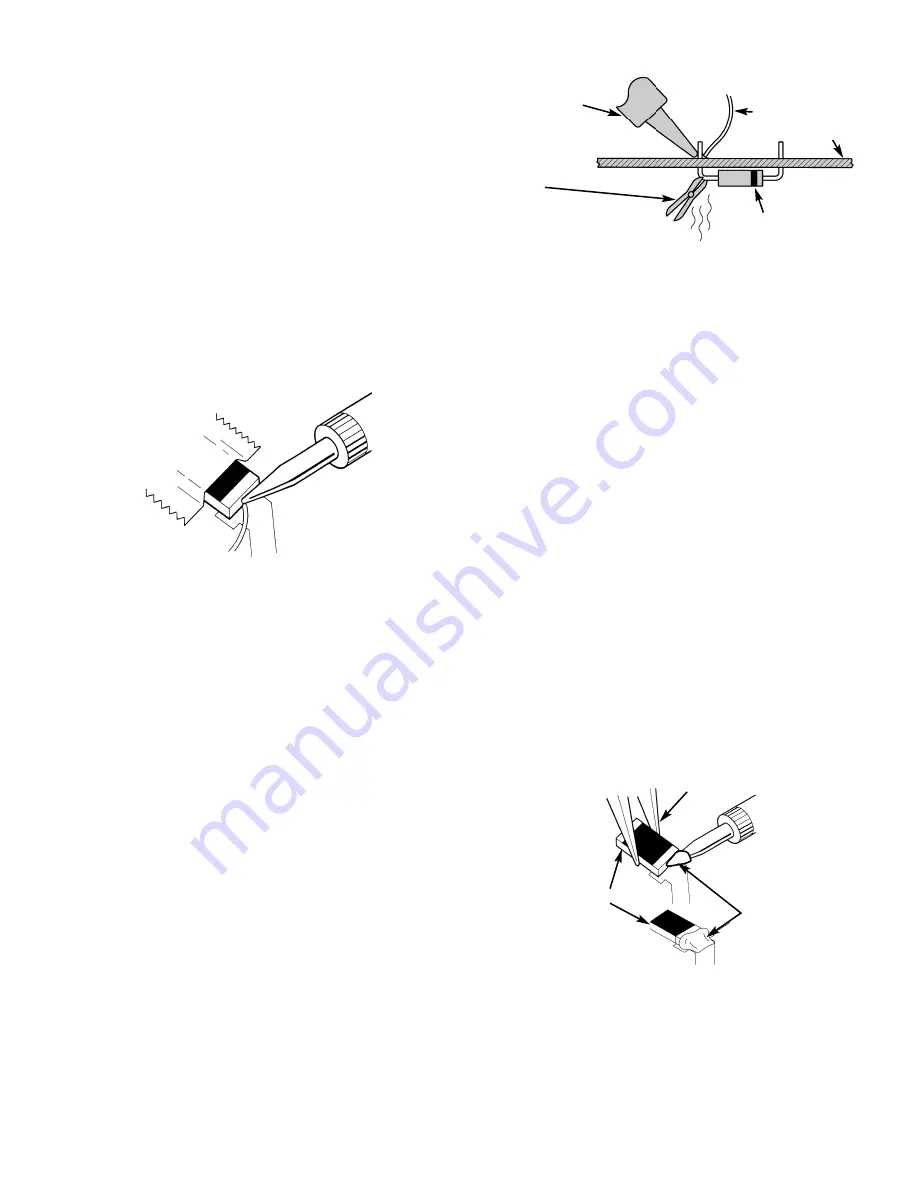

Heat Sinking

Electronic components such as transistors, IC’s, and

diodes can be damaged by the heat during soldering.

Heat sinking is a way of reducing the heat on the

components while soldering. Dissipating the heat

can be achieved by using long nose pliers, an

alligator clip, or a special heat dissipating clip. The

heat sink should be held on the component lead

between the part and the solder joint.

Soldering Surface Mount Components

1. Using tweezers, place the surface mount

component on the PC board pads and secure in

place with tape (see Figure 7A).

2. Apply a small amount of solder to the soldering

iron tip. This allows the heat to leave the iron and

flow onto the foil.

3. Place the iron in contact with the PC board foil.

Apply a small amount of solder simultaneously to

the foil and the component and allow them to

melt the solder.

4. Remove the iron and allow the solder to cool. The

solder should have flowed freely and not lump up

around the component.

5. Remove the tape and solder the other side of the

component.

When soldering the transistors, diodes and

integrated circuits, the following procedure may

be used:

1. Place the component on the PC board pads and

secure in place with tape.

2. Apply a small amount of solder to the soldering

iron tip.

3. Place the soldering iron tip on top of the

component lead to be soldered and apply solder

simultaneously to the lead and the PC board foil.

4. Remove the iron and allow the solder to cool. The

solder should have flowed freely and not lump up

around the component.

After a component is completely soldered, each

solder joint should be inspected with a magnifying

glass. If the solder has not flowed smoothly, a bad

solder joint is indicated. This occurs when the

component and pad have not been heated sufficiently.

To correct, reheat the connection and if necessary

add a small amount of additional solder.

Another way to solder surface mount components is

as follows:

1. Apply a small amount of solder to the soldering

iron tip as shown in Figure 7B.

2. Using tweezers, hold the component on the PC

board pads.

3. Apply the soldering iron simultaneously to the

component and pad and allow the solder to flow

around the component.

4. Remove the soldering iron and allow the

connection to cool.

Tweezers or Pliers

Solder

Soldering Iron

Surface Mount Component

Heat Sink

(this can be ordered as part of

Elenco’s Solder Ease Kit Model

SE-1 - see Page 6).

Soldering Iron

Solder

Heat Sensitive

Component (Diode)

PC Board

Figure 7B

Figure 6

Tape

Iron

Solder

Figure 7A