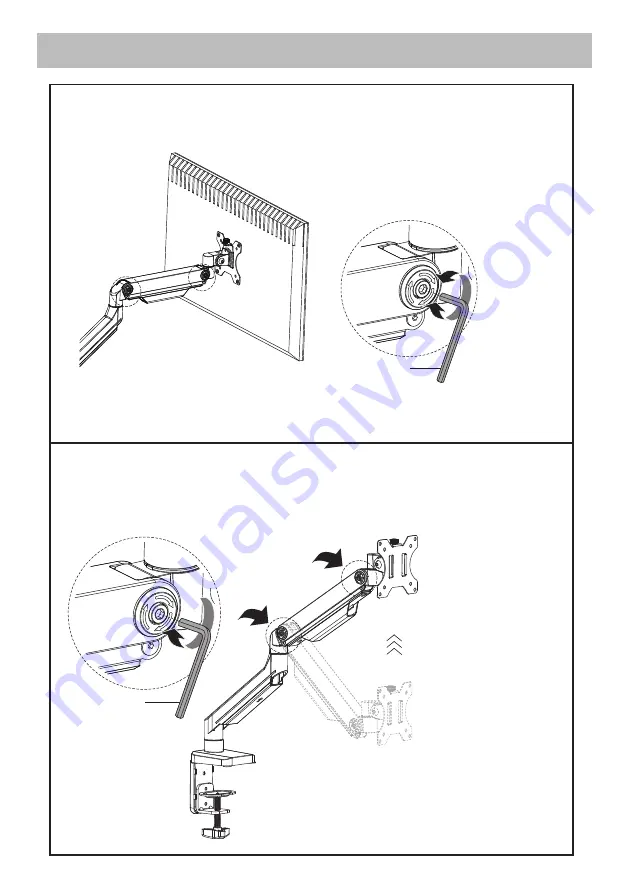

STEP 4 Adjust the tension

pop up

Note: If the clockwise rotation is too tight,

the spring will be too dull and it is difficult

to adjust the arm up and down.

We suggest not to adjust it to be too tight,

but to control your strength.

Adjust the spring tension until it supports your monitor to an optimal position.

The initial spring setting will be in a reasonable range, and generally you don't need to adjust the

spring tension.

Case 1: Monitor/Arm falls down (after install your monitor)

If your monitor is too heavy and causes the monitor to sink, turn clockwise to increase spring

tension till it can hold the weight of your monitor. (Press the arm to make it keep it in horizontal

position and then use the Allen Key to adjust the screw on the arm. )

O

O

08