20

Caution:

1. Do not use the work of inertia driving machine.

2. Do not dig, do not push the bucket teeth into the ground using the inertia of the

driving machine. This can overload the back of the machine and damage the drive

track.

3. Do not pull out completely the hydraulic cylinder piston rod. This results in a

shortening of the life of the machine. Leaving to work as much as possible backlash.

4. Do not use the work of inertia of the falling bucket.

5. Do not dig by dropping the boom or bucket to use as a pick. Digging combined with

stroke or continuous hitting can damage the operating system.

6. Do not perform lifting.

Caution!

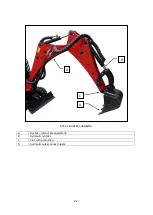

During work, always leave the support to the ground, so that the machine received

appropriate support.

Warning:

Pay attention for diffrences in machines stabillity, depending on the angle of rotation

of the body.

5.6.

Transport

While transporting the machine, follow the existing rules on weight, width, height, length and

anchoring loads.

Remove grease, oil, mud, ice, etc., from ramps or platform surface to prevent slipping off the

machine.

5.7.

Loading

1. Turn on brakes of transporting vehicle

2. Put blocks under the wheels of transporting vehicle

3. Secure the ramps

- check the strength, width, length and thickness of the plank ramps is sufficiently safe for loading,

-

pay attention to the angle of ramps was 15 ⁰ or less.

4. Check that the left and right ramp are the same height.

5. Ride slowly to the ramps.