25

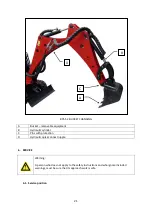

All points where parts are in move must be properly lubricated. Below there is exepmplary

lubrication point, All these points are equipped with grease nipples.

It is required to lubricate every time before working.

PIC.6.4 POINT OF LUBRICATION

A

Grease nipple

6.5.

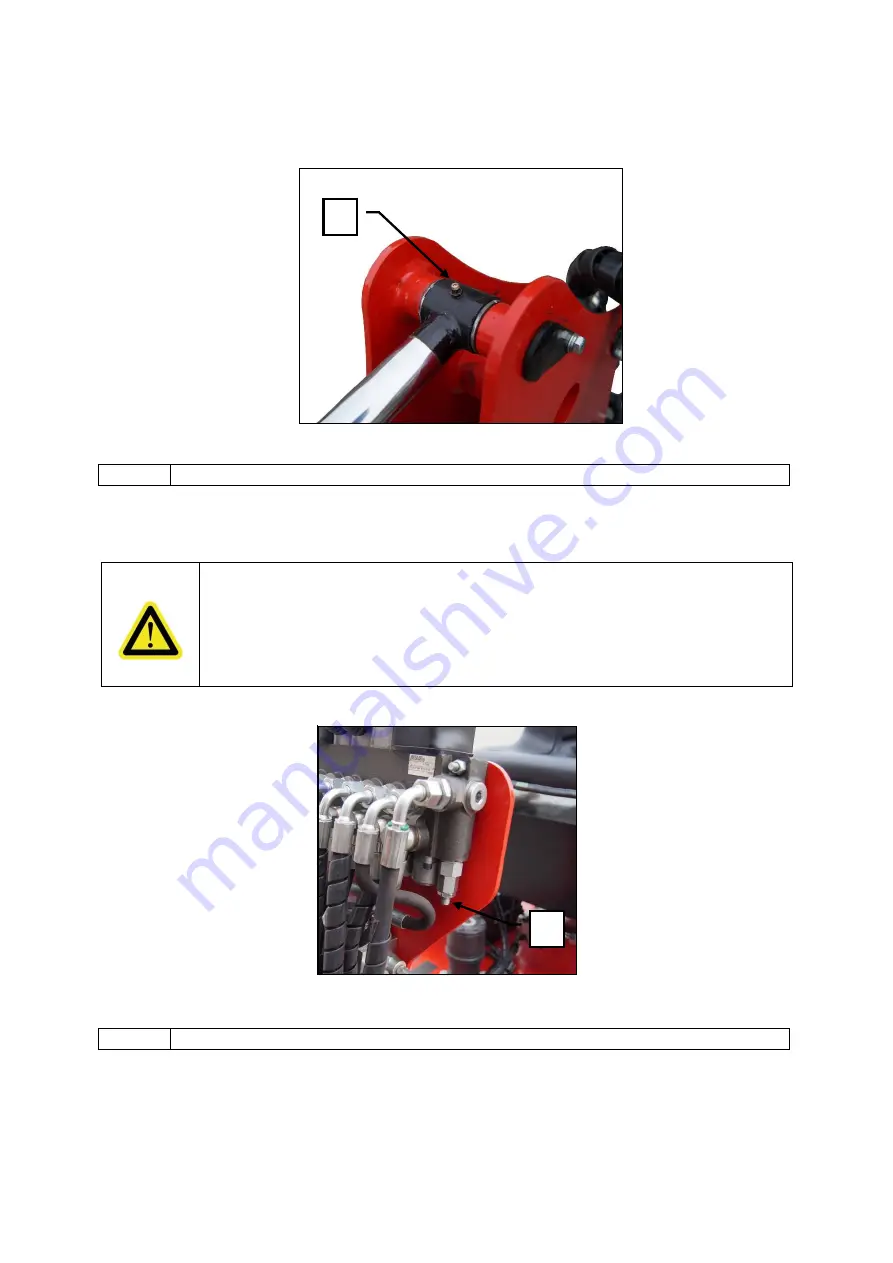

Hydraulic pressure control

Warning:

Working pressure of the hydraulic system is factory-set to 160 atm. Regulatory made

only in justified cases. Changing the operating pressure is not recommended for

unexperienced users..

PIC.6.5 HYDRAULIC PRESSURE CONTROL

A

Hydraulic pressure controler

6.6.

Tracks tension regulation

A

A