14

Potential Effect

Recommended

Action(s) of Failure

Potential Causes

Recommended Actions

Lamp does not turn

ON

Electronic Control does not

work. Due to Over Voltage

a) Pressing any key the LCD lights up and Icons are in place?

Yes, Proceed with the following diagnostic sequence

No, Replace the control and user interface.

The lamp was not screwed

correclty

1) Remove lamp cover.

2) Screw the lamp until it reaches the end of the socket.

3) Verify.

Non functional lamp

1) Remove the lamp.

2) Verify the lamp to be non functional reviewing that the filament is

not burned and be in correct place.

3) Replace if needed.

4) Verify

During the hood cleaning, the

motor connector has been loose

and a false contact in the main

harness is performed.

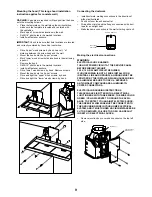

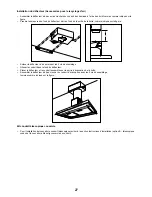

1) Open the control box removing the 6 screws.

2) Remove power supply from the hood.

3) Verify that the connector coming from the motor is well connected

to the connector mounted in the plastic verifying that the locking

system in the connectors is well locked.

4) If the connectors are not well connected:

- Hold and press main connectors attached in the white plastic.

- Push inwards the motor/lamp connectors until the locking system on

connectors is well attached.

5) Connect hood to power supply and verify.

FAN does not work

Electronic Control does not

work. Due to Over Voltage

a) Pressing any key the LCD lights up and Icons are in place?

Yes, Proceed with the following diagnostic sequence

No, Replace the control and user interface.

During the hood cleaning, the

motor connector has been loose

and a false contact in the main

harness is performed.

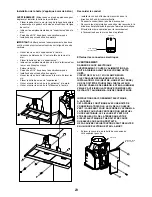

1) Open the control box removing the 6 screws.

2) Remove power supply from the hood.

3) Verify that the connector coming from the motor is well connected

to the connector mounted in the plastic and that the locking system in

the connectors is well locked.

4) If the connectors are not well connected:

- Hold and press main connectors attached in the white plastic.

- Push inwards the motor/lamp connectors until the locking system on

connectors is well attached.

5) Connect hood to power supply and verify.

The blower is

too noisy

Filters are dirty

1) Verify that the grease and/or charcoal filters are clean.

2) If they are not clean change charcoal filter, or wash

grease filter and verify.

False contact in the

connectors

During the hood cleaning, the

motor connector has been loose

and a false contact in the main

harness is performed.

1) Open the control box removing the 6 screws.

2) Remove power supply from the hood.

3) Verify that the connector coming from the motor is well connected

to the connector mounted in the plastic and that the locking system in

the connectors is well locked.

4) If the connectors are not well connected:

- Hold and press main connectors attached in the white plastic.

- Push inwards the motor/lamp connectors until the locking system on

connectors is well attached.

5) Connect hood to power supply and verify.

The hood and or

the lamp does not

work

A terminal or connector is loose

1) Open the control box removing the 6 screws.

2) Remove power supply from the hood.

3) Verify that the connector coming from the motor is well connected

to the connector mounted in the plastic and that the locking system in

the connectors is well locked.

4) If the connectors are not well connected:

- Hold and press main connectors attached in the white plastic.

- Push inwards the motor/lamp connectors until the locking system on

connectors is well attached.

5) Connect hood to power supply and verify.

Trouble shooting