27

EN/IEC 61000-3-2; EN/IEC 61000-3-3; ETSI EN 301 489-

1;ETSI EN 301 489-17; ETSI EN 300 328; IEC 62311:2019.

Suggestions for a correct use in order to reduce the

environmental impact: Switch ON the hood at minimum

speed when you start cooking and kept it running for few

minutes after cooking is finished. Increase the speed only in

case of large amount of smoke and vapor and use boost

speed(s) only in extreme situations. Replace the charcoal

filter(s) when necessary to maintain a good odor reduction

efficiency. Clean the grease filter(s) when necessary to

maintain a good grease filter efficiency. Use the maximum

diameter of the ducting system indicated in this manual to

optimize efficiency and minimize noise.

Use

The hood is designed to be used either for exhausting or filter

version.

Extraction version

In this case the fumes are conveyed outside of the building by

means of a special pipe connected with the connection ring

located on top of the hood.

CAUTION

!

The exhausting pipe is not supplied and must be purchased

apart.

Diameter of the exhausting pipe must be equal to that of the

connection ring.

CAUTION

!

If the hood is supplied with active charcoal filter, then it must

be removed.

Filtration version

The aspirated air will be degreased and deodorised before

being fed back into the room.

In order to use the hood in this version, you have to install a

system of additional filtering based on activated charcoal.

Note:

The recycled air in the charcoal filter is sent back to the

kitchen through a duct which conveys air on a side of the

cabinet.

The models with no suction motor only operate in ducting

mode, and must be connected to an external suction device

(not supplied).

The connecting instructions are supplied with the peripheral

suction unit.

Installation

Note:

The installation must be performed so that accessibility

to the hood and its electronic components is always ensured

for possible technical assistance interventions.

Note

: the cable that connects the remote motor to the hood is

3 metres long

Caution! Do not cut the cable between the hood and the

engine to avoid losing your right to warranty!

Mounting

Before starting to mount the appliance, make sure that no

component is damaged, otherwise contact the dealer and stop

mounting. In addition, read all the instructions below carefully.

•

Use an air outlet pipe no longer than 5 metres.

•

Limit the number of curves in the duct since each curve

reduces the suction effectiveness equivalent to 1 linear

metre. (E.g.: if two 90° curves are used, the duct should

be no longer than 3 metres).

•

Avoid drastic changes of direction.

•

Use a duct with 150mm diameter constant for the whole

length.

•

Use a duct made of standard complying material.

•

In case of failure to observe the instructions above, the

supplier can not be held responsible for capacity or noise

problems and no warranty will be granted.

•

Before making the hole, make sure that the inside of the

cabinet, near the hood housing area, does not have the

structure of the cabinet or other particulars which may

cause problems for the proper installation. Make sure

that the overall dimensions of the hood and the hob ae

compatible with the cabinet and therefore the installation

is feasible.

•

Before inserting the screws into the cabinet, make sure

that the product is perfectly perpendicular to the worktop.

Panel Assembly

(only for models where the panel is not supplied with the

hood)

CAUTION

!

Installation must be carried out only by qualified installers.

FOR THE INSTALLER: Responsibility for installation of the

hood, including verification of the conformity of any fixing kit

supplied with the product, is the sole responsibility of the

installer. Following is a non-exhaustive list of helpful

instructions for the installer:

- use a fireproof PANEL (compliant with art. 30 of IEC/EN

60335-2- 31), suitable for the operating temperature (at

least 80°C) and humidity (at least 93%) reached during use;

−

total weight of PANEL used should not exceed 2,5 kg;

−

secure the PANEL to the hood using the fixing points. See

the illustrations dedicated to assembly of the panel not

supplied with the hood.

−

use suitable mechanical parts to fix the PANEL (not

included in the assembly kit). Elica denies all liability for

damage to persons or property resulting from incorrect

installation of the gypsum panels and/or product.

Summary of Contents for GETUP BL MAT/A/90

Page 3: ... M1 M2 a 5 ...

Page 4: ...1 754 862 785 270 2 300 94 303 198 300 110 24 64 82 737 min 749 max ...

Page 5: ... 60 112 850 7 90 90 6 r3 3 A s s P P 864 2 100 ...

Page 6: ... 60 100 850 B P P ø150mm 11 1 11 2 4 3 ...

Page 7: ...5 b FRONT a L 754mm b a a L 64mm L max 20mm M1 M2 ...

Page 8: ...1 2 6 M1 M2 a b ...

Page 9: ...7 M1 M2 3 2X M4x15a 4 ...

Page 10: ...8 M1 M2 ...

Page 11: ...2X ø3 5X9 5 1X ø4 5X16 3X ø3 5X9 5 1X ø4 5X16 2X 90 10 9 2X ...

Page 12: ...11 1 FRONT 8X FRONT FRONT 2 1 ...

Page 13: ...11 2 BACK 8X 8X BACK FRONT BACK 8X 1 2 3 ...

Page 14: ...V Hz 12 13 1 2 3 4 ...

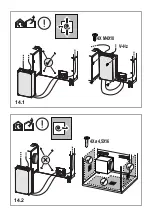

Page 15: ...4X M4X10 4X ø4 5X16 V Hz 14 1 14 2 ...

Page 16: ...15 1 cm2 cm2 Ø 150 mm 16 2 P1 1 2 ...

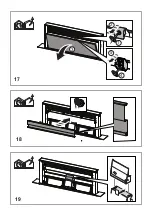

Page 17: ...19 18 17 1 2 3 4 5 ...

Page 18: ...20 21 23 2x 2x ...

Page 19: ......

Page 189: ...6 21 ...

Page 190: ...5 ...

Page 191: ...4 ...

Page 192: ...3 2 5 ...

Page 193: ...2 ...

Page 194: ...1 ...

Page 195: ......

Page 196: ...LIB0163215 Ed 10 20 ...