28

English

speeds up the entire process.

• When inserting branches, the thickest end of the branch will have to be introduced into the

feed hopper first.

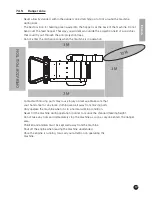

• It is best to feed the branches at the right hand side of the hopper. That way the chips sit in

the shredding chamber for a longer period before being sucked towards the turbine. It also

ensures that the chips are smaller in size.

• In the event that the volume of leaves to processed is very large, ELIET recommends to

alternately shred leaves and branches.

• Cease the operation immediately when you hear unfamiliar sounds. Stop the engine

(emergency stop bracket) and examine the cause of the sound. Perform any necessary repairs

before continuing.

• Should you notice that, despite all of the preparations made, a foreign object still has found its

way into the machine, the motor must be shut off immediately. Remove the foreign object and

check for damage. Any defects must be repaired before reassuming operation.

• The engine should, in principle, shut down automatically when the shredding chamber is

opened. If it does not as a result of an electrical defect, the operator immediately must turn off

the engine manually and refrain from using the machine until it has been repaired.

• If the shredding chamber gets clogged up, switch off the machine to remove the blockage.

Make sure to wait for the blades to come to a complete standstill before carrying out any

operation on the machine.

• Do not forget that the impeller must suck in air to be able to transport the cuttings through

the blow chute. For this reason you must make sure that the air supply is not blocked when

feeding the green waste.

• Avoid that a lump is formed when feeding green waste in bulk: it might cause blockage of the

entire passage to the entrance of the shredding chamber.

• To reduce the size of the cuttings and optimise the cutting process it is recommended to feed

branches on the right hand side of the feed opening to the shredder chamber as much as

possible.

9.6.3 What to do when the engine stalls

Overloading, overfeeding, blockage of the discharge, fuel shortage, a closed fuel tap, insufficient

oil, the safety handle in the wrong position and improper closure of the shredding chamber

are all possible causes of a stalling engine. The chipper can be easily restarted in these cases.

Proceed as follows:

1.

Check the petrol level in the tank (see § 9.2 Refuelling).

2.

Remove any branches from the feed opening.

3.

Lightly pull the starter cord to verify whether the blade axis is still blocked. As soon as you

feel resistance and are unable to pull the cord any further, simply release the cord. It is use-

less to pull the cord forcibly as this could cause it to break or overload the starter mecha-

nism.