37

English

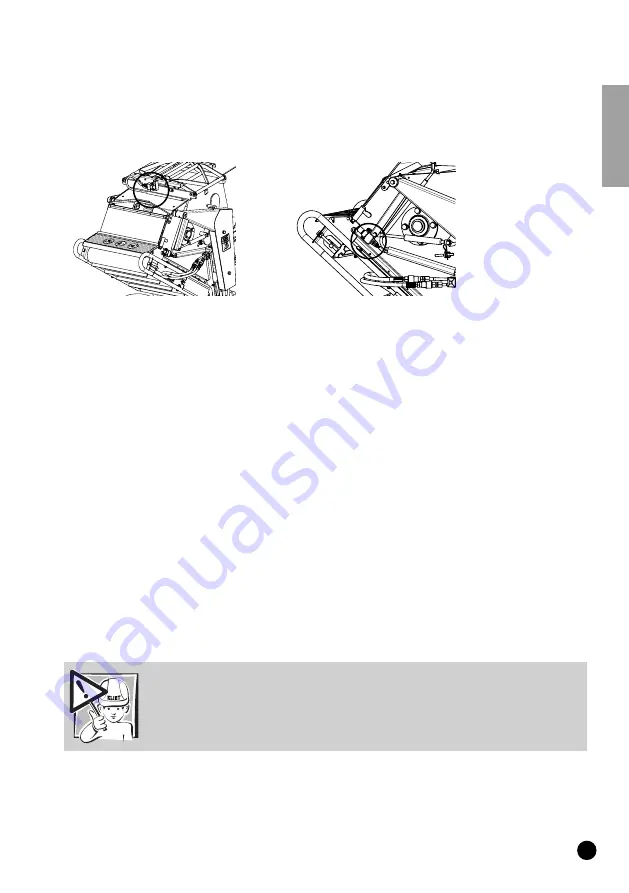

C. Safety switch activated

Two integrated safety switches ensure that the operator is not given undesired

access to moving machine parts or dangerous areas while the machine is in operation:

• One can be found on the larger safety guard.

(1)

• One can be found on the discharge belt conveyor.

(2)

This safety switches will interrupt the ignition of the engine when activated. A mechanical or

electrical fault of this switch may stop the machine without warning while shredding. Perform

checks on the following control points in chronological order to spot the possible failure:

• First check whether the shielding panels and discharge belt conveyor are fastened correctly so

that the switch is fully pressed.

• Verify that the switch is still correctly attached. A switch can become loose or shift due to vibration.

• Check the wiring of the switch for an open of damage.

• Measure the correct operation of the switch using an resistance meter at every output (NO

circuit/NC circuit).

• Repair or replace as appropriate and restart the machine.

D. Overloading

Although the machine is equipped with an Anti Engine Blockage system (ABM), the blade system

may become blocked due to a piece of wood due to an unfortunate set of conditions. This will

also cause the engine to stop since it is not disengaged.

• Open the shredding chamber (see AP.A-P3).

Caution:

The blades are razor-sharp and, therefore, always wear gloves

and avoid touching the blades.

• Remove the chippings form the shredding chamber.

• Verify that a piece of wood is not stuck in the area between the feed roller and blade shaft.

• If the blade shaft is jammed, release it (see § 9.7.5).

(1)

(2)