65

English

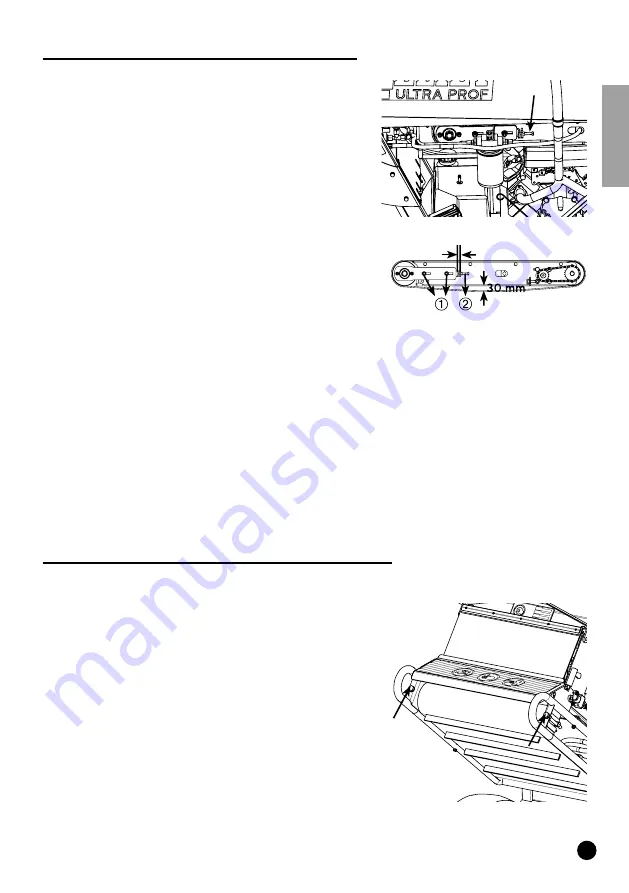

11.5.5 Tightening the feed belt for correct tension

Although the feed belt runs slowly and experiences little

dynamic load, stretching will in due course also occur. The

tension of the feed belt must, therefore, also be regularly

adjusted (every 200 working hours.)

• Always switch off the engine and remove the key from

the ignition before performing maintenance tasks.

• Open both safety guards to get access to the feed belt

adjustment arrangements (see § AP.A-P1).

• There are two tensioning guides (one to every side) on

the front roller each secured with two M10 bolts.

• Turn these four nuts

(1)

a little bit to remove the ten-

sion on the guide plate. (A/F 17.)

• A bolt presses against the tensioning guide.

(2)

This can be

used to variably adjust it. Loosen the lock nut (M8) and turn the pressure bolt (M8) clockwise so that the

guide roller presses forwards and the belt is uniformly tensioned. (A/F 13)

• Carry this out uniformly on both sides so that the roller will not take up a slanted position.

• If the conveyor belt can be pulled away 30 mm at the bottom of the body, then tension is correct.

• Measure the distance from the rear of the guide plate to the support block of the pressure bolt on

both sides. (see drawing). Turn the pressure bolts further until this distance is the same on both sides.

• Correctly tighten the securing bolts (M10). (A/F 17)

• Once the bolts

(1)

have been tightened, the tension is removed from the pressure bolt

(2)

which allows you to have the bolt just touching the guide. Retighten the lock nut.

• Carefully replace all safety guards after carrying out the maintenance tasks.

11.5.6 Tightening the discharge belt for correct tension

The discharge belt conveyor will be subjected to sagging

(stretching) after a number of working hours. The tension

of the belt must be adjusted to ensure the drive roller can-

not slip and damage the belt.

• Always switch off the engine and remove the key from

the ignition before performing maintenance tasks.

• Open both safety guards to get access to the feed belt

adjustment arrangments (see § AP.A-P1).

• The central shaft around which the top roller runs has been

provided with a tensioning device on both sides. To retension

the belt, pull the roller up using two adjustment bolts (M8).

• First loosen the lock nut (M8) (A/F 13) and next turn the

adjustment bolt clockwise.