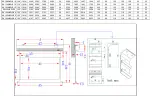

MZ04242018

3

Installation Instructions

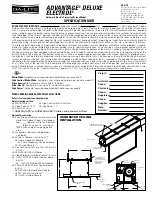

For installation assistance, please consult a professional Installer. EliteScreens is not liable for faulty installations.

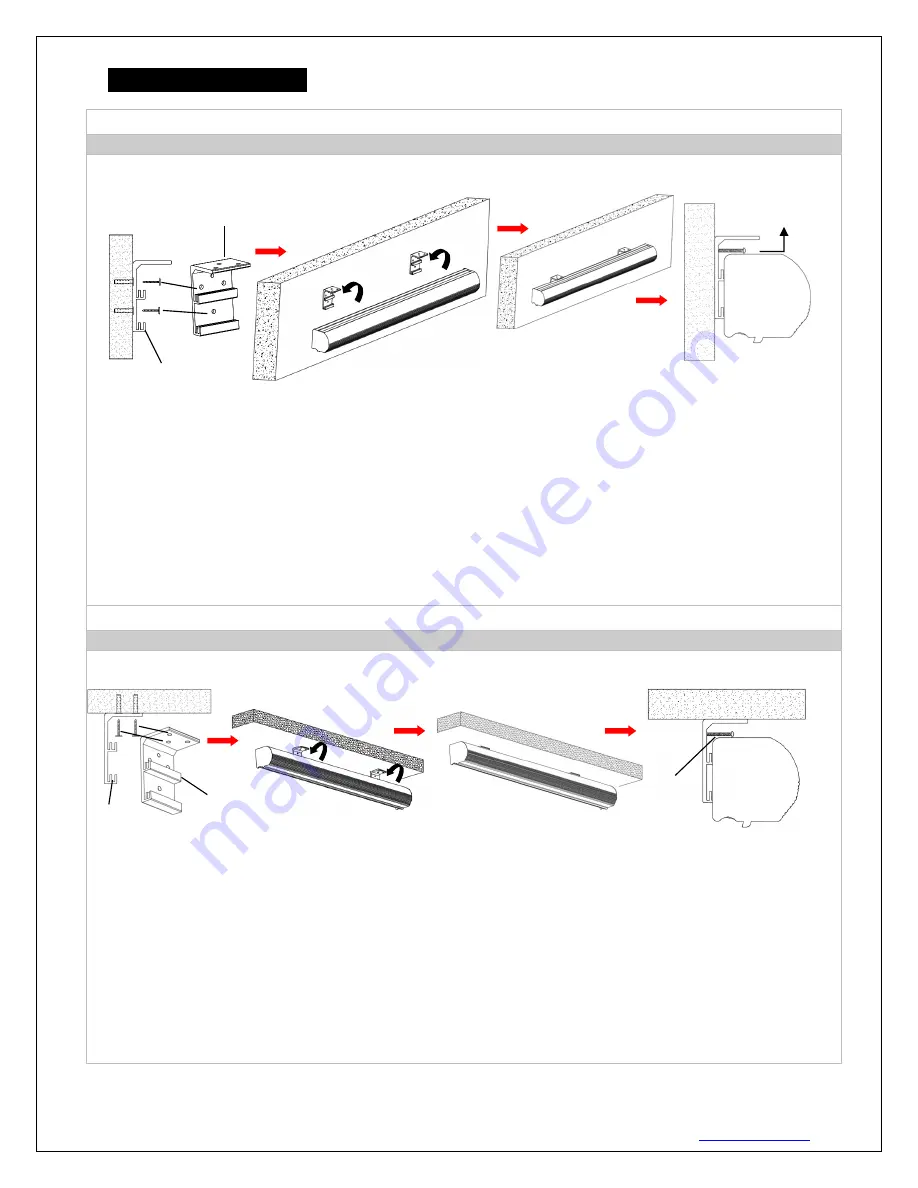

A. Wall Mount

Flush hidden mount (movable position)

This mount method allows the screen to slide horizontally.

1.

Determine where the screen will be installed. Then, measure and mark the distance between the top and

bottom screw holes from each

Wall/Ceiling mount bracket

(A).

2.

Drill a hole on all marked points and install the brackets with the

dry-wall anchor

(C),

M5x60 screw

(B),

Make sure both brackets are properly leveled.

3.

Hang the screen by placing the

lower

“catch” located on the back over the brackets

upper

“catch”.

4.

After making sure the screen is secured, you can slide it left / right to properly center it in position.

5.

Lastly, screw the

M5 screw

(F) into the upper hole of the bracket to add additional support for the screen.

Two or more people are required while one holds the screen in place.

B. Ceiling Mount

I.Ceiling Mount (movable position)

This mount method allows the screen to slide horizontally.

1.

Determine where the screen will be installed. Then, measure and mark the distance between the top and

bottom screw holes from each

Wall/Ceiling mount bracket

(A).

2.

Drill a hole on all marked areas and install the brackets with the

dry-wall anchor

(C),

M5x60 screw

(B),

Make sure both brackets are properly leveled.

3.

Hang the screen by placing the

lower

“catch” located on the back over the bracket’s

upper

“catch”.

4.

After making sure the screen is secured, you can slide it left / right to properly center it in position.

5.

Lastly, screw the

M5 screw

(F) into the upper hole of the bracket to add additional support for the screen.

Two or more people are required while one holds the screen in place.

Front view of bracket (A)

M5x25MM round

head cross screws

(F)

Side view of bracket (A)

Wall

Front view of

bracket (A)

Side view of

bracket (A)

M5x25MM

round head

cross screws (F)

Ceilin

g