Page 30 of 130

Doc No.

:

T202001006

Reverse installation

1754N±360N

1754N±2594N

Vertical installation

1554N±360N

1554N±2594N

6.5 Installation of the End/Tool Effector

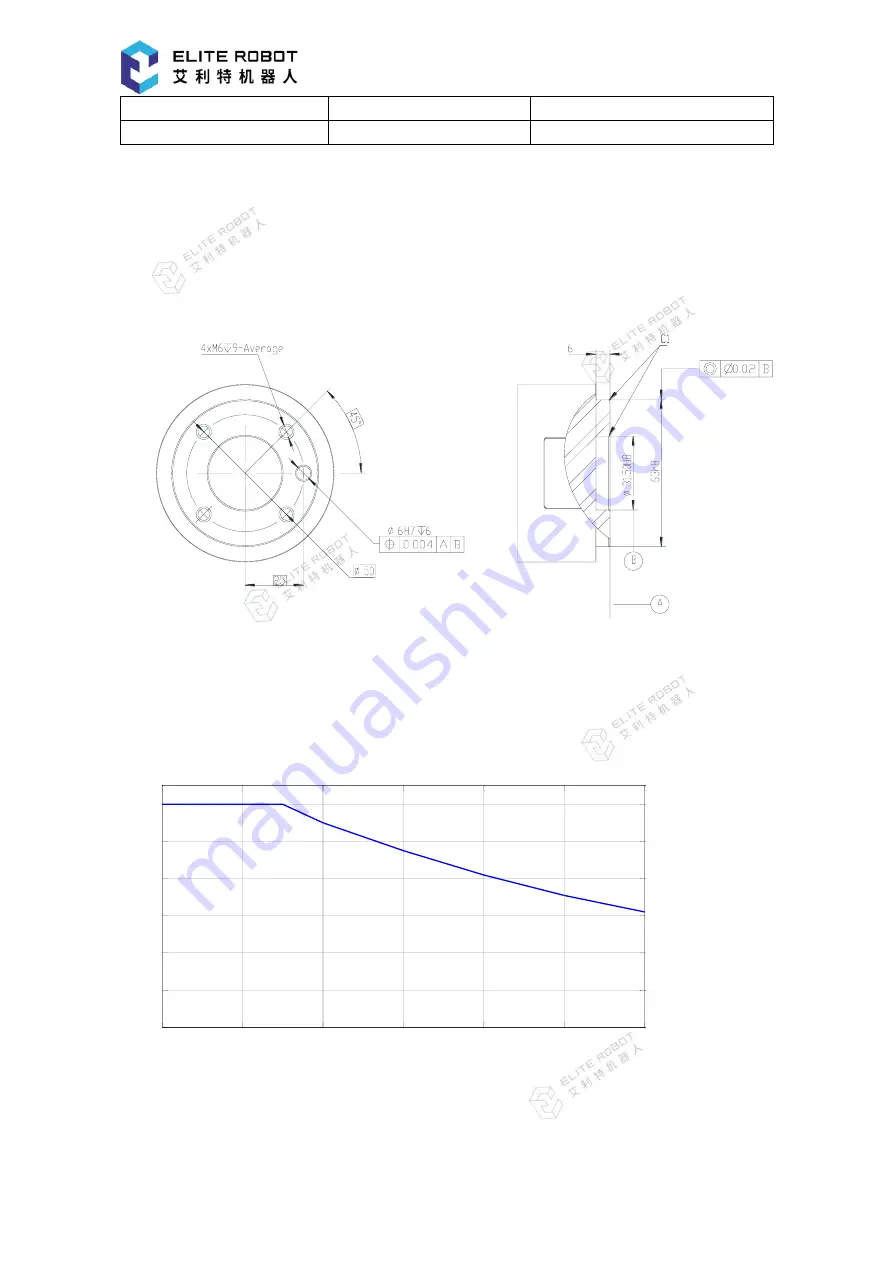

The tool flange has four M6 threaded holes and one Ф6 positioning hole, in this way the clamp

may be conveniently installed and connected to the robot end. The mechanical dimensions of the tool

flange are shown in Figure 6-5.

Figure 6-5 Mechanical dimensions diagram of the tool flange of the robot, with unit of mm

1. Make sure the tool is correctly and securely installed in place.

2. Make sure the tool is safely constructed such that it cannot create a hazardous situation by a

dropping part unexpectedly.

A wrist payload diagram is shown above. Herein, the horizontal ordinates D respectively

indicates the offset of the center of gravity. The offset of the center of gravity is the distance from the

center of the flange plate of the tool/end effector to the center of gravity of the tool.

0

100

200

300

400

500

600

0

2

4

6

8

10

12

D(mm)

P

a

yl

o

a

d

/

K

g