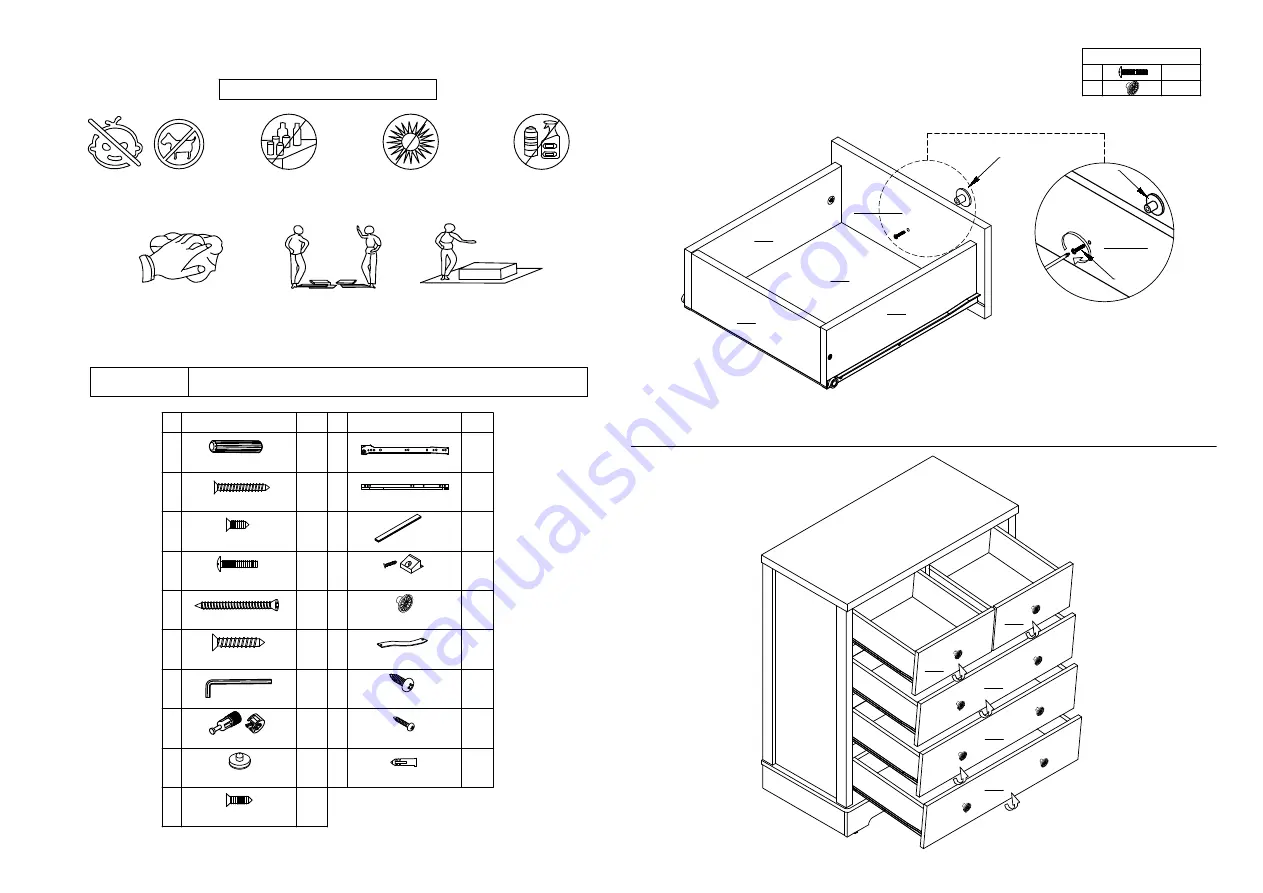

IMPORTANT TIPS AND MAINTENANCE

i)Keep children and animal away

from working area because smaller

part could choke if swallowed.

ii)Never put the liquid or damp

on the furniture.

iii)To avoid dulling, do not

place directly to the sunlight.

iv)Never use ammonia cleaning

product, because it will damage

to finish.

v)Use a soft or damp cloth (dry

cloth)and then wipe to clean on

the surface.

vi)Two person are required.

vii)Put the soft map on the

floor to protect the furniture

before assembly.

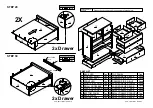

COMPONENTS :-

HARDWARE

Please check you have all the fittings part or tools are listed in below.

CCO-TB117-WHT / PAGE 2

FITTINGS/TOOLS

NO.

NO.

QTY

QTY

FITTINGS/TOOLS

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

DOWEL 6x30MM

ALLEN KEY

CAM BOLT+CAM NUT

69

Pcs

10

Pcs

30

Pcs

35

Sets

4

Pcs

4

Pcs

M6X50MM

K.

1

Pc

SCREW M3.5x16MM

8

Pcs

HANDLE SCREW 19MM

DRAWER RUNNER A - L/R

SCREW M4 X 30MM

HANDLE

SCREW M3.5 X 12MM

SCREW M4 X 38MM

L.

DRAWER RUNNER B - L/R

M.

PVC H

N.

8

Sets

PVC SUPPORT

PVC GLIDE

O.

8

Pcs

P.

2

Pcs

Q.

2

Pcs

ANTI TIP-STRIP

M4 X 16MM

R.

S.

2

Pcs

2

Pcs

M4 X 25MM

PVC WALL PLUG

72

Pcs

6

Pcs

1

Pc

10

Pcs

10

Pcs

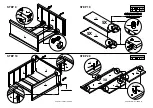

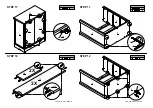

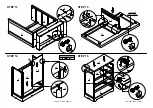

CCO-TB117-WHT / PAGE 19

STEP 31

STEP 32

HARDWARE NEEDED:

D.

O.

2PCS

2PCS

D

O

20&21

O

2x Drawer

20&21

19

15

14

22

16

20

21

16

16