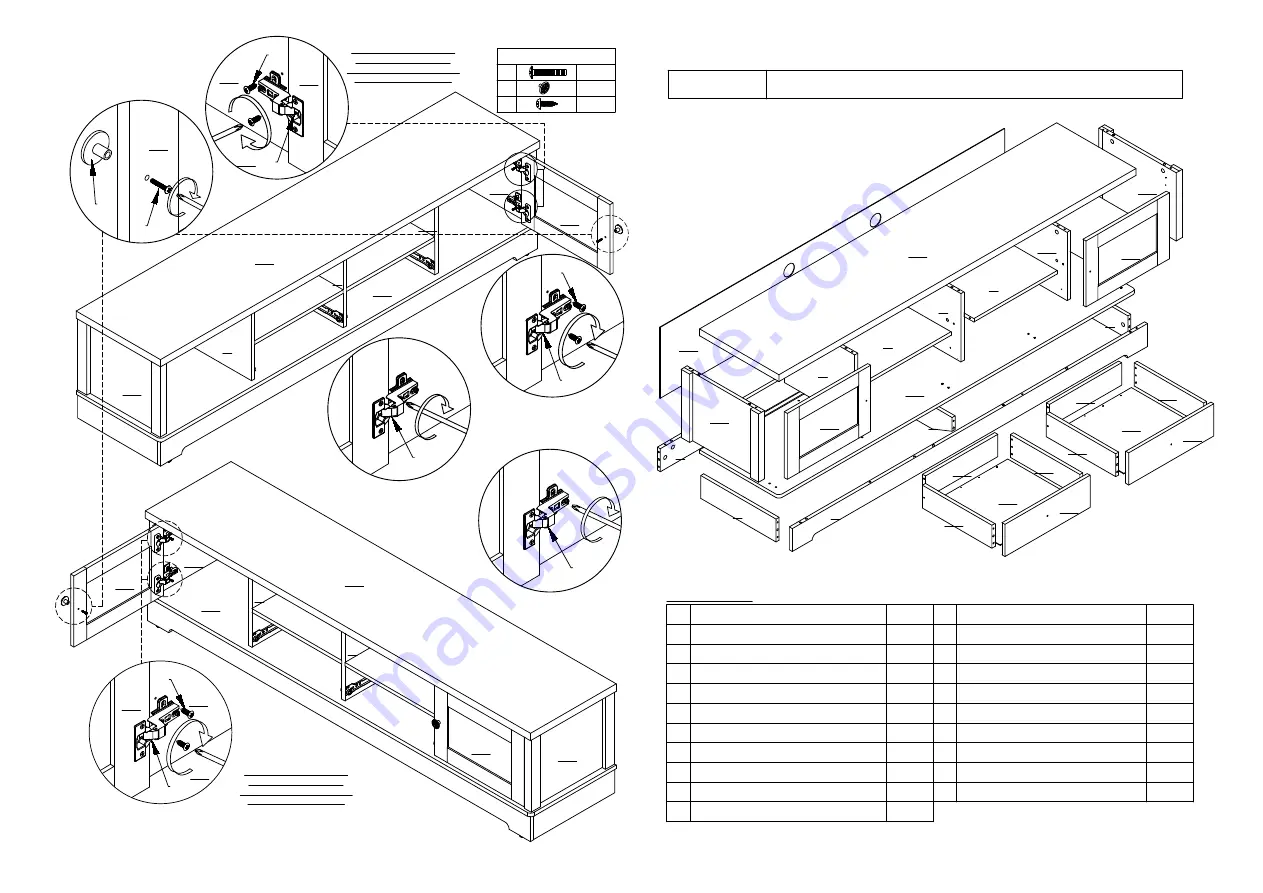

Please check you have all the panels are listed below.

COMPONENTS :-

PANELS

CCO-TV180-WHT / PAGE 3

PART LIST

1

2

3

4

CENTRE PANEL

SHELF PANEL_RIGHT

5

CENTRE PANEL_LEFT

SHELF PANEL_LEFT

CENTRE PANEL_RIGHT

6

7

8

9

10

SIDE LEG_RIGHT

CENTER LEG

SIDE LEG_LEFT

DRAWER BACK

FRONT LEG

1pc

1pc

1pc

1pc

11

12

13

14

15

16

17

18

19

20

21

TOP PANEL

SIDE PANEL_LEFT

BACK PANEL

SIDE PANEL_RIGHT

BOTTOM PANEL

DRAWER SIDE_LEFT

DRAWER SIDE_RIGHT

DRAWER BASE

DRAWER FRONT

DOOR PANEL

BACK LEG

1pc

1pc

1pc

1pc

1pc

1pc

2pcs

2pcs

6

7

8

10

9

11

12

13

15

1

4

3

2

5

14

16

17

18

19

20

21

21

16

17

18

19

20

2pcs

2pcs

2pcs

2pcs

1pc

1pc

1pc

1pc

1pc

STEP 29

2. LATERAL

ADJUSTMENT BY

SCREW ADJUSTING

1. VERTICAL

ADJUSTMENT

VIA SLOT IN THE

MOUNTING PLATE

3. FRONT-TO-BACK

BY THE SLACKING

THE HINGE ARM

MOUNTING SCREW

HARDWARE NEEDED:

F.

8PCS

D.

O.

YOU SHOULD RE-ADJUST

SCREWS AS SHOWN TO

ALIGN DOOR ONCE HINGES

HAVE BEEN ATTACHED

F

M

1.

M

2.

M

3.

F

M

21

13

15

F

M

21

12

15

YOU SHOULD RE-ADJUST

SCREWS AS SHOWN TO

ALIGN DOOR ONCE HINGES

HAVE BEEN ATTACHED

CCO-TV180-WHT / PAGE 18

12

13

9

10

6

21

11

15

21

21

12

15

13

21

6

9

11

O

D

2PCS

2PCS