The EWPC 961 is a temperature

controller specifically designed for

refrigeration applications and pro-

vides time control for off-cycle de-

frost management.

GENERAL DESCRIPTION

The EWPC 961 is a temperature controller

specifically designed for refrigeration appli-

cations and provides time control for off-

cycle defrost management.

It incorporates an output relay for com-

pressor control and a PTC sensor input.

A number of parameters are displayed al-

phanumerically to set up the instrument for

each specific application.

The EWPC 961 is supplied in the popular

“32x74” ELIWELL.

OPERATION

The EWPC 961 is designed to operate

strictly as a cooling control, which means

that the switching differential is positive:

the compressor cuts off at setpoint and is

started at a temperature of set plus differ-

ential. The on-board microprocessor pro-

vides several timing functions for the

defrost; the defrost cycle as well the de-

frost cycle duration are user selectable.

At the start of each defrost cycle, the com-

pressor is simply stopped, regardless of

the temperature control circuit.

In addition, the EWPC 961 offers several

system protection features, all easy to un-

derstand and easy to program.

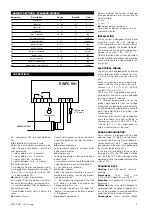

FRONT KEYPAD

SET

: push to display the setpoint temper-

ature; the “DEF/SET” status light will blink.

The setpoint can be changed within 5 sec-

onds with the “UP” or “DOWN” button.

The control will automatically switch back

to normal operating mode within 5 sec-

onds; the last entered setpoint will stay in

memory.

UP

: used to increase the setpoint value, as

well as the parameter when in program-

ming. When held down for a few seconds,

the change rate accelerates.

DOWN

: same functions, except to de-

crease a value.

DEFROST

: push to initiate a manual de-

frost cycle (override of programmed de-

frost start; programmed time resets to

zero). Manual defrost can not be started

while in setpoint or in parameter program-

ming mode. This button must be activated

for 3 seconds to start a defrost; the

“DEF/SET” status light will come on and

the compressor is stopped.

Led “COMP”

: status light of the compres-

sor output.

Led “DEF/SET”

: blinks during setpoint

display/change. When Led is on the de-

frost is in progress.

PARAMETER PROGRAMMING

Programming is easily accessed by hold-

ing the “SET” button down for more than

4 seconds; the first parameter is displayed

while the status light “DEF/SET” remains

blinking during the programming period.

Other parameters are accessed with the

“UP” and “DOWN” button.

With the “SET” button, the actual setting of

each parameter is displayed. To change a

parameter setting, push the “SET” plus the

“UP” (or “DOWN”).

The system will automatically return to its

normal operating mode a few seconds af-

ter the programming procedure is com-

pleted or interrupted.

DESCRIPTION OF PARAMETERS

d

: differential.

LS

: Lower Set.

Setting of the lower user-access setpoint

limit.

HS

: Higher Set.

Setting of the upper user-access setpoint

limit.

CA

: CAlibration.

Temperature read-out offset to allow for

possible error due to probe location.

rP

: relay Protection.

Select relay status in case of probe defect.

on = compressor ON in case of probe de-

fect;

HOW IT IS MADE

• Housing: black ABS plastic, self-

estinguishing

• Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm

(2.637")

• Protection: the instrument front-

panel is waterproof IP65; an op-

tional snap-on cover can be

supplied to provide additional pro-

tection of the rear terminal block

• Connections: screw terminal

block (2.5 mm

2

; one wire each ter-

minal onl)

• Display: 12.5 mm LED (0.50")

• Push buttons: located on front

panel

• Output: one (1) SPDT relay 8(3)A

250V

a

• Input: PTC probe

• Resolution: 1 °C (°F)

• Accuracy: better than 0.5% of full

scale

• Power supply (depending on mod-

el): 12 V

a

/

c

or 24 V

a

/

c

WHAT IT IS

EWPC 961

freezer controls