ID 985/S/E/CK - ID985/E LX

2/14

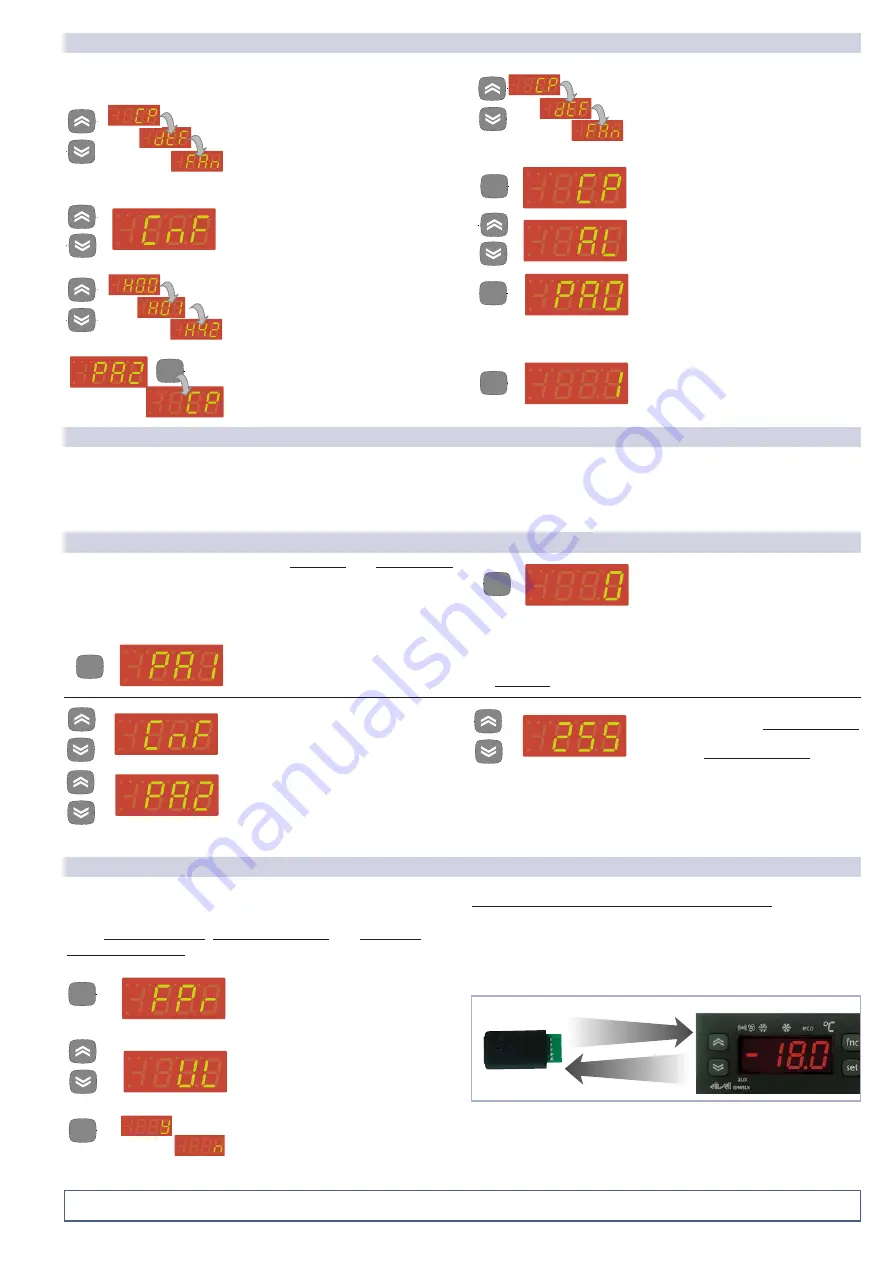

The menu is divided into 2 levels once users have pressed the ‘set’

button for 5 seconds, they can access the user level folders (1)

Navigation at user level(1):

•

By using the ‘UP’ / ‘DOWN’ buttons

you can scroll through all the folders in

the programming menu that only contain

user level parameters (1)

How to access the installer level (2):

•

By using the ‘UP’ / ‘DOWN’ buttons, scroll

through the user level folders (1) until the

folder with the “CnF” label is displayed.

Then press ‘set’ to access the parameters

contained in it.

•

By using the ‘UP’ / ‘DOWN’ all the para-

meters in the user level (1) in ‘CnF’ are dis-

played, continue until the ‘PA2’ label is not

longer displayed and press ‘set’.

•

By pressing the ‘set’ button next to ‘PA2’

the first folder containing installer level

parameters will be displayed and then the

‘CP folder.

Navigation at installer level(2):

•

By using the ‘UP’ / ‘DOWN’ buttons

you can scroll through all the folders in

the programming menu that only con-

tain installer level parameters (2)

How to modify the parameter value (on both levels):

•

When the ‘set’ button is pressed, the

first folder in the menu is displayed.

(e.g.: “CP” folder)

•

By using the ‘UP’ / ‘DOWN’ buttons

you can scroll through all the folders in

current level.

•

By pressing the ‘set’ button next to

the selected folder (in this case “AL”) the

first parameter in the current level will

be displayed. Select the desired parame-

ter using the ‘UP’ / ‘DOWN’ keys.

•

By pressing the ‘set’ button the value

of the selected parameter is displayed

and by using the ‘UP’ and ‘DOWN’ but-

tons, it can be modified.

set

set

set

set

set

set

PROGRAMMING MENU

set

set

The Copy Card is an accessory connected to the TTL serial port

used for quick programming of the unit parameters (upload

and download parameter map to one or more units of the same

type). upload (UL label), download (dL label) and copy card

formatting (Fr label) operations are performed in the following

way:

•

The ‘FPr’ folder contains the com-

mands necessary for use of the Copy

Card. Press ‘set’ to access the func-

tions.

•

Use the ‘UP’ / ‘DOWN’ buttons to

display the required function. Press the

‘set’ and uploading (or downloading)

will be performed.

•

If the operation is successful ‘y’ will be

displayed, if it is not successful, ‘n’ will

be displayed.

Download from reset

Connect the copy card when the instrument is OFF. The program-

ming parameters are downloaded when the device is switched

on. At the end of the lamp test, the following messages are dis-

played for about 5 seconds:

• dLY label if copy operation is successful

• DLn label if operation fails

NOTE

:

• after the parameters have been downloaded, the device uses

the downloaded parameter map settings.

•

see

“FPr folder” in Parameter Table and Description of parameters

set

set

set

set

UPLOAD

DOWNLOAD

COPY CARD

the CnF folder is displayed.

•

Press the ‘set’ button to enter the ‘CnF’

folder where the‘PA2’ label is present.

•

Scroll through the folder parameters

and press the ‘set’ button next to the

‘PA2’ label, ‘0’ will appear on the dis-

play.

•

Use the ‘UP’ / ‘DOWN’ buttons to select

the correct value of the installer password

and then press the ‘set’ button to access

the installer level parameters (2).

If the password is not entered correctly, the device will display the ‘PA2’

label again and the operation will have to be repeated.

At each level in both menus, when the “fnc” button is pressed or the 15 second time out elapses, you are taken back to the higher

display level and the last value on the display is stored.

Access to parameter handling both at user level and installer level

can be limited by using passwords. The passwords can be enabled

by setting the PA1 (user password) and PA2 (installer password)

in the ‘dIS’ folder. The passwords are enabled if the value of the

2 parameters PA1 and PA2 is not 0.

•

To access the “Programming” menu hold

down the “set” button for more than 5

seconds.

If specified, the user level(1) access PASS-

WORD will be requested

•

If password 1 is enabled (not 0) you will

be asked to enter it. Perform the operation

by selected the correct value using the ‘UP’

e ‘DOWN’ keys and press the ‘set’ button

to confirm.

Installer level (2) parameters

In the programming menu scroll through the folders containing

the user level parameters using the UP’ and ‘DOWN’ buttons until

PASSWORD

set

set

KEYBOARD LOCKING

The instrument includes a facility for disabling the keyboard:

• using the keys (pressing

UP+DOWN simultaneously

for 2

seconds; see KEYS AND LEDS)

• by programming the “Loc” parameter (see folder with “diS”

label).

If the keyboard is locked, you can access the “Programming”

Menu by pressing the “set” key.

The Setpoint can also be viewed.