Fault diagnosis

53

12 Fault

diagnosis

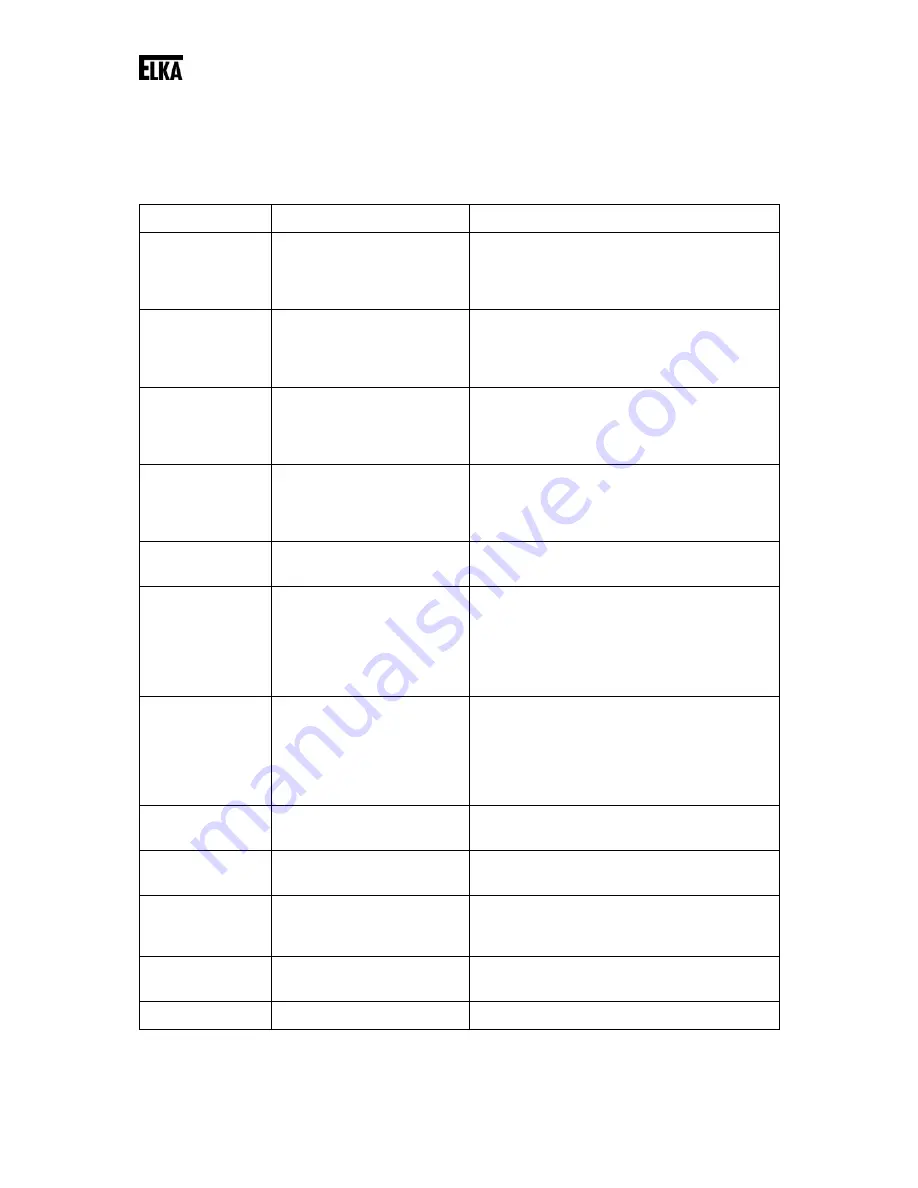

An fault is shown on the display as a code, when detected by the controller. The following faults are

recognised and displayed.

Display Fault

description

Procedure

e1

Photo-cell testing LSI failed.

Check the connected photoelectric barriers for

the interior area for function. Make sure the

1kOhm resistor is connected to the

photoelectric barrier receiver.

e2

Photo-cell testing LSA

failed.

Check the connected photoelectric barriers for

the exterior area for function. Make sure the

1kOhm resistor is connected to the

photoelectric barrier receiver.

e3

Testing safety contact

profile SLA failed.

Check the connected safety contact profiles

for direction OPEN for function. Make sure the

8.2kOhm resistor is connected as terminating

resistor.

e4

Testing safety contact

profile SLZ failed.

Check the connected safety contact profiles

for direction CLOSED for function. Make sure

the 8.2kOhm resistor is connected as

terminating resistor.

e5

Running distance exeeded

(gate was stopped).

Check end stoppers and relearn the running

distance.

e6

The power supply limit fort

he external equipment

12Vdc has been reached.

The power source load is

too high. The controller is

blocked.

Check the connected load at the terminals

12Vdc and GND (observe the max. current

drain). Check the input leads for short circuit.

e7

The power supply limit fort

he external equipment

24Vdc has been reached.

The power source load is

too high. The controller is

blocked.

Check the connected load at the terminals

24Vdc and GND (observe the max. current

drain). Check the input leads for short circuit.

e8

The memory data has been

lost / is faulty.

The controller has to be re-learned.

e9

Error in storing of data on

memory. Controller is faulty.

Return for repairs.

ea

Error in the redundant

detection of BS. Controller

is faulty.

Return for repairs.

eb

The controller detects one

of motor relays is faulty.

Return for repairs.

ec

Measuring amplifier faulty.

Return for repairs.