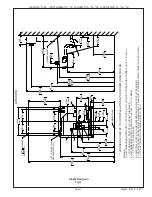

Page 5

98980C (REV. K - 08/17)

LVRCDWS*A, *2A LVRCTLDDWSC*A, *2A LVRC8WS*1A, *2A, *3A LVRCTL8WSC*1A, *2A, *3A

Fig. 4

Note: Screw the locknut hand tight to seal

Fig. 5

BOTTLE FILLER INSTALLATION

1)

Remove wall mounting plate(s)

from Cooler(s). Install Wall Mounting Plate(s) as per rough-in diagrams on sheet 2 or 3 of this instruction.

NOTE:

Mounting plate(s)

MUST

be supported securely. Add fixture support carrier if wall will not provide adequate support.

2)

For Single Model Installations:

Install water cooler onto wall bracket and secure to wall. Connect drain and water inlet to cooler as required (See rough-

in on page 2).

DO NOT

connect power to cooler at this time or turn water supply on.

2a)

For Two Level Model Installations:

Install lower water cooler only at this time onto bracket as per rough-in diagram on sheet 3.

3)

Remove VRC Bottle Filler

from carton. Remove 3/8” to 1/4” reducing union from end of waterline, (do not throw away it will be needed later). Lay Bottle Filler

on water cooler basin and cut insulation from tube even with bottom of unit, remove this insulation from the 3/8” tube, but do not discard. Feed the power

cord, and waterline through the hole on top of water cooler. Feed the Reset Button wire from circuit board down through the hole in the basin.

NOTE:

To prevent scratching the basin place a towel or soft cloth over the entire basin when working above it.

4)

With the power cord,

waterline and reset button wires through the hole on top of water cooler place Bottle Filler on to mounting bracket on basin.

(See Fig. 3). Make sure bottle filler is installed properly on the basin gasket.

5)

Once Bottle Filler

is installed on basin mounting bracket, tighten the two screws (supplied) one on each side of the bottle filler. Install Top Cover on Bottle

Filler (See FIG. 3) with two mounting screws (supplied) . Caution do not over tighten screws.

6)

For Two Level Model Installations:

Secure non-refrigerated unit to wall, connect drains and water inlet. Connect black reset button wires from

non-refrigerated unit to the black wires on the refrigerated unit (see step 4).

7)

For Single Model Installations:

Install remaining tube insulation to the water line from bottle filler, connect Bottle Filler waterline inside of the water cooler

by connecting the 3/8” water line with the 3/8” to 1/4” union and short piece of poly tube that was previously installed to the tee at the evaporator outlet.

7a)

For Two Level Model Installations:

Install the 1/4” poly tubing and insulation from the outlet of the filter to the union on top of the evaporator. Install the

1/4” poly tubing and insulation from the regulator in the non-refrigerated cooler to one of the tees at the evaporator outlet. Install remaining tube insulation

to the water line from bottle filler, connect Bottle Filler waterline inside of the water cooler by connecting the 3/8” water line with the 3/8” to 1/4” union and

short piece of poly tube that was previously installed to the tee at the evaporator of the refrigerated cooler.

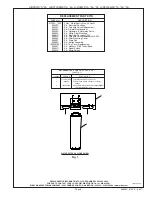

8)

Install filter cartridge,

remove filter from carton, remove protective cap, attach filter to filter head by firmly inserting into head and rotating filter clockwise.

NOTE:

If existing plumbing rough-in locations (Drain, Water In, Electric Supply) do not allow the filter to be mounted inside the cooler cabinet

the filter can be installed horizontally below the unit. A retrofit kit is available to mount the filter beneath the cooler.

9)

Turn water supply on

and inspect for leaks. Fix all leaks before continuing.

10)

Once unit has been inspected

for leaks and any leaks found corrected, plug Bottle Filler and LVRC unit into wall. Be sure to reinstall fuse to the circuit

or switch the circuit breaker back to the “ON” position.

11)

Once power is applied to Bottle Filler,

the GREEN LED light should illuminate showing good filter status along with the LCD Bottle Counter.

12)

Verify proper dispensing

by depressing the button at the top of the Bottle Filler and verify water dispenses. Note: the first initial dispenses

might have air in line which may cause a sputter. This will be eliminated once all air is purged from the line.

14)

Once unit tests out

, install Lower Panel back on LVRC water cooler(s). Unit is now ready for use.

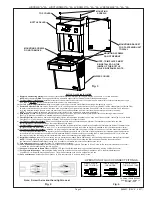

MOUNTING BRACKET

FOR FASTENING UNIT

TO WALL

TOP COVER

MOUNTING

SCREWS

Fig. 3

MOUNTING SCREWS

DO NOT REMOVE

MOUNTING SCREWS

DO NOT REMOVE

BOTTLE FILLER

WATER COOLER

NOTE: TRIM PLATES MUST

BE INSTALLED ON THE

INSIDE OF THE BOTTLE

FILLER SIDE PANEL SLOTS.

B

C

A

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

OPERATION OF QUICK CONNECT FITTINGS

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

A

B

C