21

EN

Instructions for the installer

Installation

This appliance is not provided with a

combustion product discharge. It is

recommended that it be installed in

sufficiently aerated places, in terms of the

laws in force. The quantity of air which is

necessary for combustion must not be

below 2.0 m3/h for each kW of installed

power.

See table of burner power.

Note: the device is in installation class 3.

The appliance’s adjustment parameters

are shown on the plate attached to its

housing.

Positioning

(Fig. 4). The appliance can be fitted

into a working area as illustrated

on the corresponding figure. Before

positioning the hob, fit the seal

around the entire periphery of the hole

cut in the worktop.

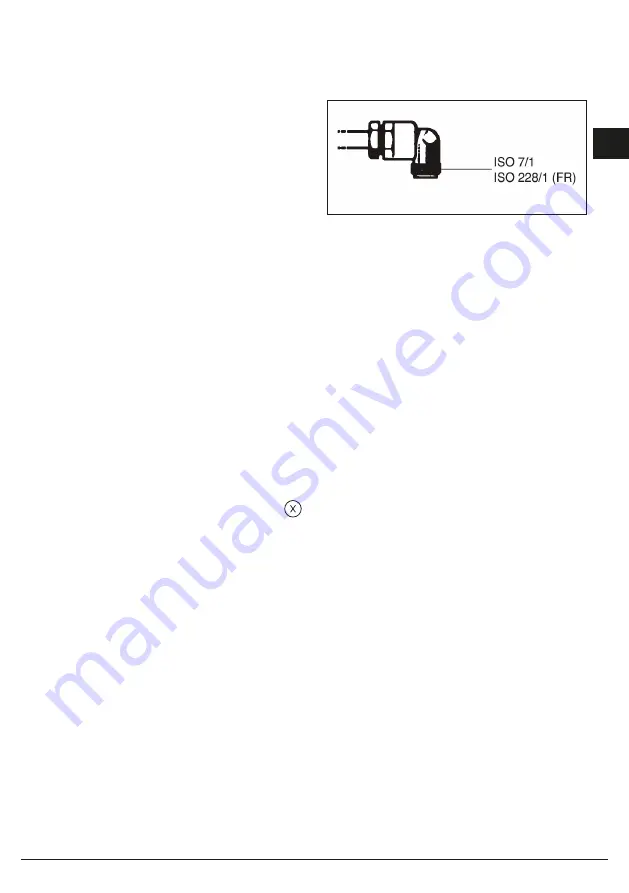

Gas connection

(Fig. 5) Connect the appliance to the gas

cylinder or to the installation according

to the prescribed standards in force, and

ensure beforehand, that the appliance

matches the type of gas available.

Otherwise, see “Adaptation to various

types of gas”.

Furthermore, check that the feed pressure

falls within the values described on the

table: “User chacteristics”.

Fig. 5

Rigid/semi rigid metal connection

Carry out the connection with fittings

and metal pipes (even flexible pipes)

so as to obtain counter stress the inner

parts of the appliance.

N.B. - when the installation has been

carried out, check the perfect sealing of

the entire connection system, by using

a soapy solution.

Electrical connection

(Fig. 6) Prior to carrying out the electrical

connection, please ensure that:

• the plant characteristics are such as

to fol- low what is indicated on the

matrix plate placed at the bottom of

the working area;

•

that the plant is fitted with an efficient

earth connection, following the

standards and law provisions in force.

The earth connection is compulsory

in terms of the law.

Should there be no cable and/or plug on

the equipment, use suitable absorption

material for the working temperature as

well, as indicated on the matrix plate.

Under no circumstance must the cable

reach a temperature above 50°C of the

ambient temperature.

If connecting directly to the mains

power supply, fit a multi-pole switch of a