10

B. Installation and inspection before each application

1.

Suspend the hoist by locating the top hook into the load carrying system and check that the

hoist rotates freely .

2.

Ensure that the hand chain and load chain hang freely and are without damage or twists

.

3.

Pull the length of hand chain through one full rotation without the load attached and check that

the chain runs easily and smoothly over the hand wheel and that a smooth clicking sound is

heard in the lifting direction.

4.

Checking load brake operation:

Lift the load approx. 50mm clear and release the hand chain.

If the load is safe and holds on the brake continue lifting to approx. 100mm and stop. Lower the

load slightly and release the chain, the load should now hold steady and not drop or slide.

5.

If the hoist brake is operating correctly, the lifting operation can now be started.

6.

Important for devices with multiple chain drops

: Check that the bottom block assembly has

not slipped through the load chain loop during transit - this can be recognized by twists in the

chain. Check that the welded seams of every other chain link are in the same direction. To

rectify chain twists - pass bottom block back through the chain loop until twists are eliminated.

7.

The end chain link must be securely fastened at the anchor point on the hoist body.

V. Operation

1. Brake closes independently when hanging on the minimal load. The minimum load is 10% of

nominal load with a minimum of 30 kg.

2. Chain block is only suitable for vertical lifting and lowering.

3.

To move the load the hand chain is either pulled on the right to lift up or the left to lower down.

VI. Chains and hooks

1. The chains and hooks have to be

inspected regularly! Clean the chain before inspection and

lubricate the load chain periodically to prevent corrosion. NEVER

lubricate the brake!

2.

Do not allow the load chain to be subjected to shock loads.

3.

Check load chain for stretch/wear.

The internal length

(t)

of a worn chain link, smallest dia. of

wire

(D)

and length over 11 chain links

(a)

are measured by a slide gauge where the chain must

be tightened firmly.

4.

Elimination Criteria: If the resulting measurements

exceed the values

(a)

in the

table below the

chain must be renewed immediately. Measurement of diameter

(D)

shall not be less than those

stated below and the link pitch

(t)

of the single chain link must not be exceeded

.

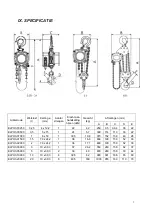

VII. Overload

protection (not fitted on 250kg models)

The overload safety device protects the

hoist by preventing it from lifting more than the default friction

connection than the hand wheel permits. The factory settings restrict the

overload safety device to

approx.150% nominal load. By tightening or loosening the nut no. 49, the pressure on the friction disc

is increased

or decreased. When the desired

value is reached, the nut no. 49 is secured by bending

one or two teeth of the toothed wheel no. 50 into the corresponding gap. (see spare parts list)

Safe

working

load (t)

Max. measurement

of (mm)

Min. chain

link

diameter

(D)

(mm)

Hook mouth

opening

(G)

normal – max.

(mm)

1 chain

link

(t)

11 chain

links

0,25

12,6

134,9

3,6

25 – 28

0,5

15,8

170,0

4,5

26 – 29

1

18,9

210,9

5,4

32 – 35

1,5

25,2

271,9

7,2

38 – 42

2

25,2

271,9

7,2

38 – 42

3

31,5

352,5

9,0

43 – 47

5

31,5

352,5

9,0

48 – 53

10

31,5

352,5

9,0

60 – 66

20

31,5

352,5

9,0

84 – 92

a