14

0420 Roto-Jet

• Replace the machine cover and test for proper assembly.

• If the machine is still sluggish and inefficient call an Elliott service facility.

• Recommended solvents for flushing are:

DEM-Kote 2X726

Loctite Safety Solvent

Inhibisol Safety Solvent

The vanes in the air motor are designed to give between 5,000 and 15,000 hours of operation under

normal conditions and with the proper lubrication. If you suspect that the machine is in need of new

vanes contact the Elliott service location. (Repair kit 04230 is available.)

Under normal conditions other lubrication of the machine between uses is not necessary, unless the

machine has been operated “Dry”. Should you wish to use the Roto-JetTM dry, the manifold drive

shaft must be lubricated with a few drops of oil. Position the machine vertically, taking care not

to damage the throttle valve or air supply coupling. Use a standard long spout oil can to place oil

behind the brass square drive coupling. Using the machine dry after it has been used for wet opera-

tion, could damage the seals and bearings, which may require replacement if not lubricated.

Clean dust and debris from vents. Keep the machine handles clean, dry and free of oil or grease.

Your machine has been finished with a two-part, epoxy, paint coating that is very durable and should

last the life of the machine. Use only mild soap and a damp cloth to clean your machine. Certain

cleaning solvents can be harmful to the painted surfaces. Never use flammable or combustible sol-

vents around machines.

After each use, drain all water from the flexshaft outer casing. Store the flexshaft by laying it down,

in a large diameter coil, in a dry, secured area.

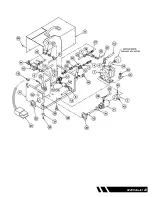

After every cleaning season or 12 months remove the machine cover and check the motor coupling

set screws for proper tightness. Inspect the coupling for alignment and verify the connections of

the tubing within the machine. Replace the cover and position the machine vertically. Lubricate the

manifold drive shaft, behind the female brass square drive coupling with a few drops of oil. An oil

can with a standard long spout will be required. Make sure the flexshaft casing is drained of all wa-

ter. Lubricate the flexshaft with a water soluble lubricant solution diluted to the manufacturers rec-

ommendations. An oil can with a standard long spout will be required. Position the spout between

the flexshaft core and the casing. Fill and drain the flexshaft from both ends. When finished, store

the flexshaft by laying it down, in a large diameter coil, in a dry, secured area. Start the next cleaning

season by operating the machine prior to starting a new job. For more information on proper opera-

tion see “Operation” section.

Summary of Contents for Roto-Jet 0420

Page 2: ......

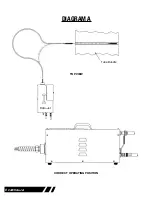

Page 8: ...8 0420 Roto Jet DIAGRAM A Tube Bundle Roto Jet TOP VIEW CORRECT OPERATING POSITION...

Page 19: ...0420 Roto Jet 19 NOTES...

Page 23: ...0420 Roto Jet 23...

Page 25: ......

Page 26: ......