Tube Tugger

11

TOOL CHANGEOVER

Changing the Nosepiece:

1. Loosen socket screws in nosepiece adapter with Allen wrench.

2. Remove nosepiece from nosepiece adapter.

3. Insert new nosepiece into nosepiece adapter.

4. Make sure that the socket screw engages into slotted ring of the nosepiece.

5. Tighten socket screw to lock in nosepiece.

Changing the Collet Set:

6. Engage spanner wrench into threaded cap and loosen cap.

7. Unthread cap from rear of Tube-Tugger.

8. Remove compression spring and thrust washer.

9. Remove set of collet jaws from Tube-Tugger.

10. Lubricate new set of collet jaws on the OD of the jaws.

11. Insert new set of collet jaws into Tube-Tugger.

12. Insert thrust washer and compression spring.

13. Thread cap onto Tube-Tugger.

14. Secure cap firmly using spanner wrench and release fork.

TABLE OF CONTENTS

Introduction ......................................................................2

Safety...............................................................................3

Start-up ............................................................................4

Quick Reference Diagram................................................5

Operation ......................................................................6-7

Tool Changeover .............................................................8

Tool Selection Guide / Specifications ..............................9

TOOL CHANGEOVER

Changing The Nosepiece:

1.

Loosen socket screws in nosepiece adapter with Allen wrench.

2.

Remove nosepiece from nosepiece adapter.

3.

Insert new nosepiece into nosepiece adapter.

4.

Make sure that the socket screw engages into slotted ring of the nosepiece.

5.

Tighten socket screw to lock in nosepiece.

Changing The Collet Set:

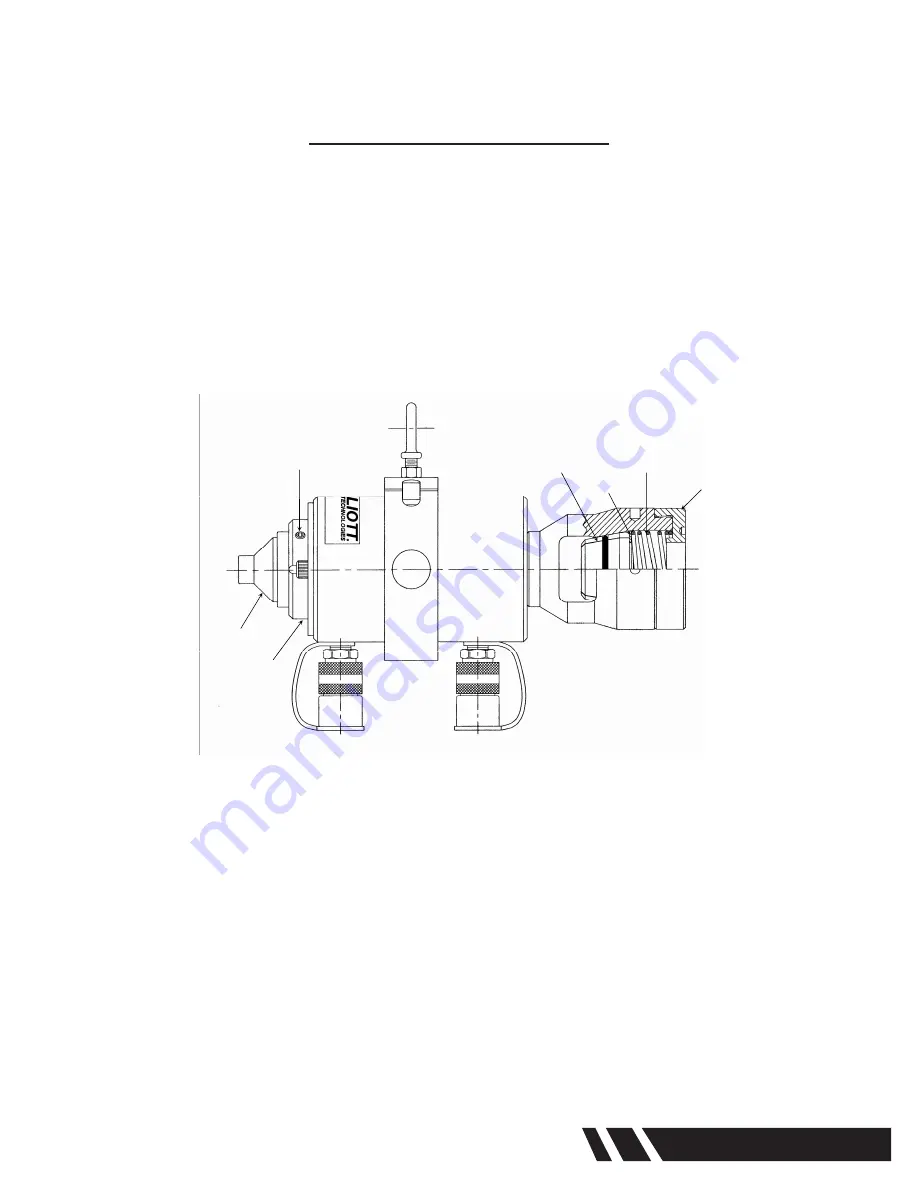

Thrust Washer

Collet Set

Diagram E

Socket Screw

Nosepiece

Nosepiece

Adapter

Threaded Cap

Compression Spring

1.

Engage spanner wrench into threaded cap and loosen cap.

2.

Unthread cap from rear of Tube-Tugger.

3.

Remove compression spring and thrust washer.

4.

Remove set of collet jaws from Tube-Tugger.

5.

Lubricate new set of collet jaws on the OD of the jaws.

6.

Insert new set of collet jaws into Tube-Tugger.

7.

Insert thrust washer and compression spring.

8.

Thread cap onto Tube-Tugger.

9.

Secure cap firmly using spanner wrench and release fork.

Page 8

Elliott Tube-Tugger

TM-36

TM-36

Elliott Tube-Tugger

Page 1

Summary of Contents for Tube Tugger

Page 2: ......