9

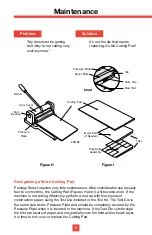

Figure H

Figure I

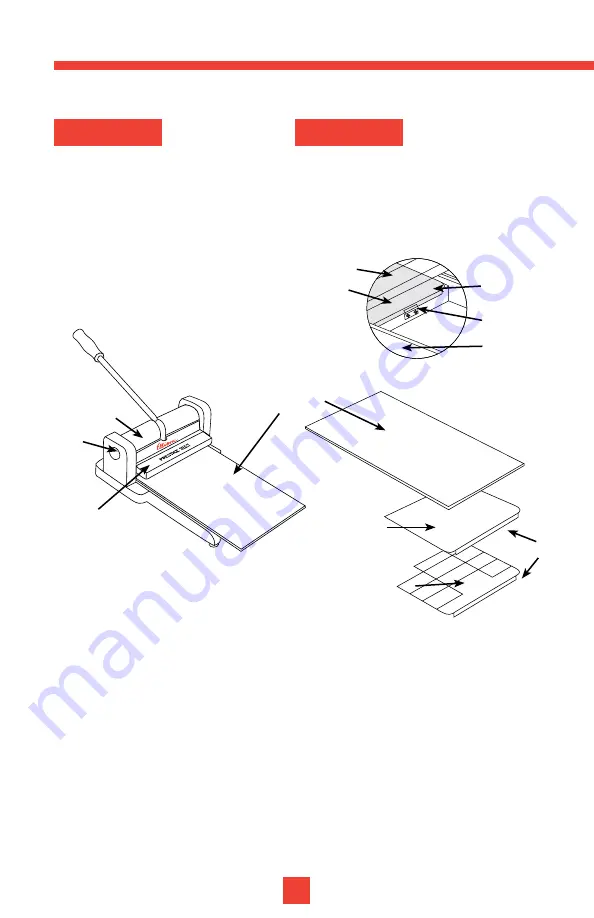

Cutting Pad

Step Shim

Assembly

BACK

End

Bearing

FRONT

Mylar Shim

(If Needed)

Cam Cover

Shim Clip

Pressure Plate

Mylar Shim

Side Rail

Tab

Inset

Pressure

Plate

Tabs

“My dies must be getting

dull–they’re not cutting very

well anymore.”

It’s not the die that needs

replacing–it’s the Cutting Pad!

Problem

Solution

Recognizing a Worn Cutting Pad

Prestige Select requires very little maintenance. After considerable use (usually

four to six months), the Cutting Pad (Figures H and I) will become worn. If the

machine is not cutting effectively, perform a test cut with four pieces of

construction paper, using the Test Die included in the Tool Kit. The Test Die is

the same size as the Pressure Plate and should be completely covered by the

Pressure Plate when it is inserted in the machine. If the Test Die cuts through

the first two layers of paper and only partially cuts the third and/or fourth layer,

it is time to turn over or replace the Cutting Pad.

Maintenance