Care and maintenance tasks

70

BA_Elmasolvex_VA_EN_Vers.05.2018

© Elma Schmidbauer GmbH

9.1.2

Cleaning the cleaning chamber

At least once a day (according to needs).

Visually inspect the cleaning chamber for residues and soiling.

In doing so, particularly check the area of the heater

(

Fig. 9.1.4.1.E

) for adhesions.

Due to the increased surface temperatures in this area,

discolouration and deposits can increasingly occur.

If required, clean the cleaning chamber with a cloth moistened

with alcohol (e.g. IPA).

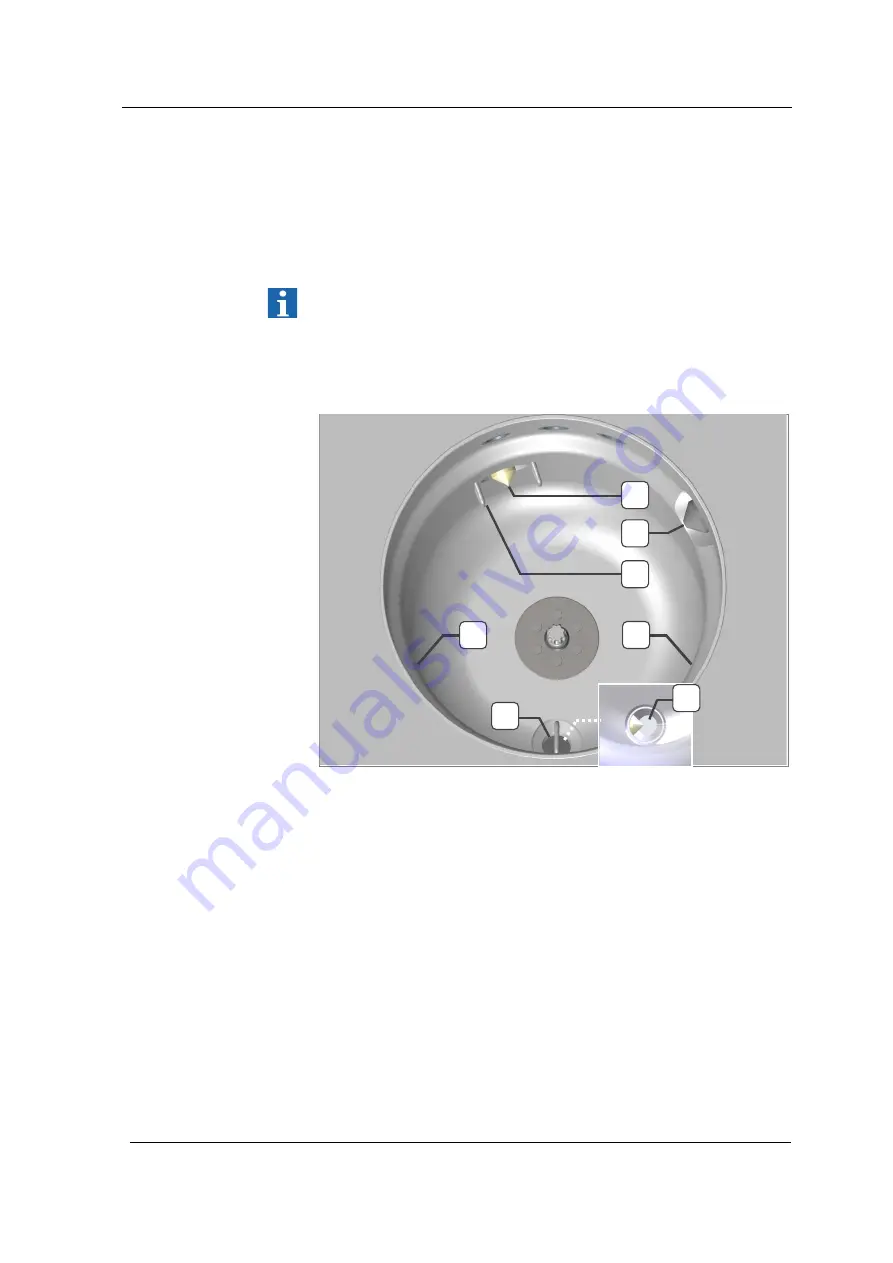

Fig.9.1.2.1 View of cleaning chamber

Filling level sensor

Work level

Filling level sensor

Overfilling level

Guard bar

(2 per sensor)

Sieve insert

(mesh size 0.36 mm) for collecting lost precision

parts and coarse particles when draining the cleaning / rinsing

liquid from the cleaning chamber. The sieve can be unscrewed

for cleaning.

When reinstalling the sieve, it must be screwed in carefully as

far as the stop. Check freedom of movement of the cleaning

basket afterwards (collision hazard if the sieve insert has not

been screwed in correctly).

Heating areas

/ radiating surfaces of the 2 heaters with radiant

heat for the drying process.

Filling level sensor

Empty level (installed under the sieve

insert).

Recommended interval

Inspection criteria

Procedure

A

B

C

D

E

F

D

F

B

A

E

E

C