\\Elmacron-server\Gemensam\Instruktioner\Instruktioner i W ord\1005RE\Engelska\1005RE-ORP%E.doc

- 3 -

-

Senast utskrivet 2007-10-11

11:16

2. INSTALLATION

2.1 CASING

1005RE is housed in a robust splash-proof plastic glassfiber reinforced case with a transparent

front cover. The protection class is IP 67.

2.1.1 Dimensions

2.2 MOUNTING

The instrument is designed for wall

mounting. Be sure that the instrument is

mounted at a non-vibrating place.

Mounting is done with four screws (

∅

7 - 9

mm). Fastening is carried out through the

four mounting brackets at the rear side of the

instrument.

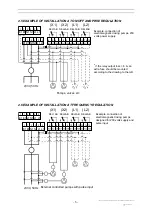

2.3 CONNECTIONS

2.3.1 Preparation

Loosen the 4 plastic screws that hold the instrument front part, at the same time as the front is

kept on place with one hand.

Loosen carefully the front part, and fasten the front parts lower pair of screws in the bottom parts

upper pair of holes, using manual power.

Be sure that the flat conductor cable between the front and the bottom circuit cards does not

stretch too much.

Now the instrument is accessible for connections.

When the connections are done, the front part is put back on place.

It is recommended that each instrument is provided with a separate power switch.

The electrode coax cable must be protected by a screen and may not be installed near power cables.

Avoid extension of cables.

The connections consists of:

195

185

185

31

0

300