5

Technical Support: +44(0)23 9269 6638 (option 3)

PAK200824_01A May 2017 ©2017 ELMDENE INTERNATIONAL LTD

Cable Sizing

1)

Mains input cable must be to the applicable standard with a 5A or greater current capacity, i.e. 0.75

mm

2

nominal conductor area, having a minimum operating voltage of 300/500 Vac.

2)

The low voltage output cable must be sized to carry the rated load current to the devices connected

to the PSU.

3)

All cabling should be securely fastened in position.

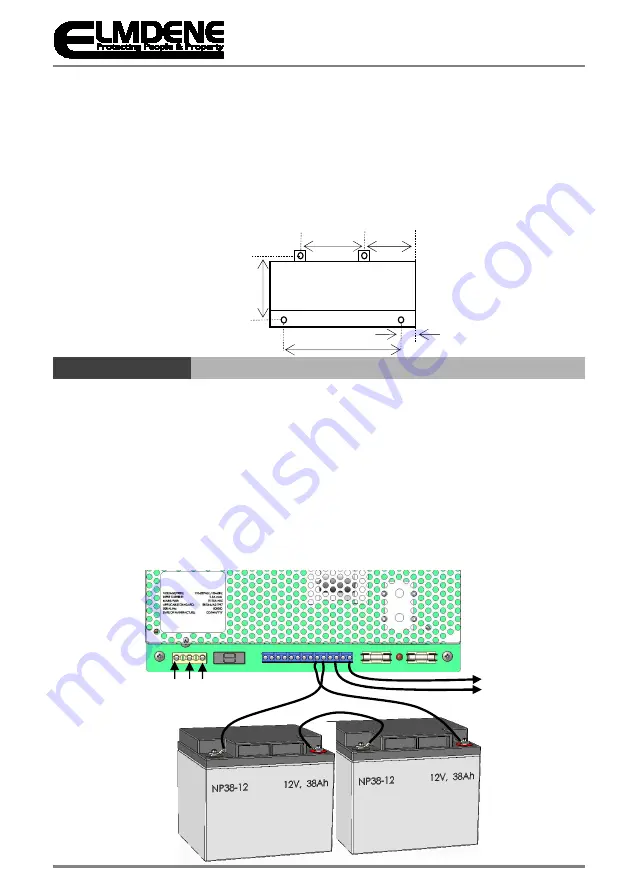

Mounting the Module

4)

Fix the module into the chosen enclosure using 4 x fixing points as per Fig 1 (All fixings must be

used). Ensure sufficient space for heat dissipation and adequate ventilation to avoid overheating of

the unit or associated batteries.

Figure 1 - Fixing points

C

OMMISSIONING

Mains Power Up

1)

With no external connections made to the PSU, connect the mains input wires to the terminal

block,

ensuring that the mains isolator (disconnect device) is open

. Fasten wiring in place with

cable tie to saddle.

Note: Equipment must be earthed.

2)

Apply mains input. Ensure that the green Mains LED illuminates and that the yellow Fault LED

flashes after approximately 20s (indicating a disconnected battery).

3)

Disconnect the mains power.

Load Output and Remote Signalling

4)

Connect the EPS and PSU Fault outputs to the appropriate inputs of control equipment if remote

fault monitoring is required.

+

+

+

-

To Load

L E N

-

+

-

10mm

Module Dimensions

245L x 135W x 60D (mm)

84mm

130mm

222mm

126mm