Gold Solo Whistle Installation Guide

MAN-G-SOLWHIIG-EC (Ver. 1.509)

|Basic Recommendations|

www.elmomc.com

22

Table of Contents

6.1.

Basic Recommendations

6.1.1.

General

1.

Use shielded cables. For best results, the cable should have an aluminum foil shield covered

by copper braid, and should contain a drain wire.

Use 24, 26 or 28 AWG twisted-pair shielded with drain wire cables.

2.

Keep the cable as short as possible.

Do not mount the power cables of the motor and power bus in the proximity of the control

and feedback cables.

3.

Ensure that in normal operating conditions, the “earth connection” wires and shield of the

control cables

carry no current.

The only time these conductors carry current is under

abnormal conditions, when electrical equipment has become a potential shock or fire

hazard while conducting external EMI interferences directly to ground, in order to prevent

them from affecting the drive. Failing to meet this requirement might result in

drive/controller/host failure.

4.

After completing the wiring, carefully inspect all wires to ensure tightness, good solder of

joints and general safety.

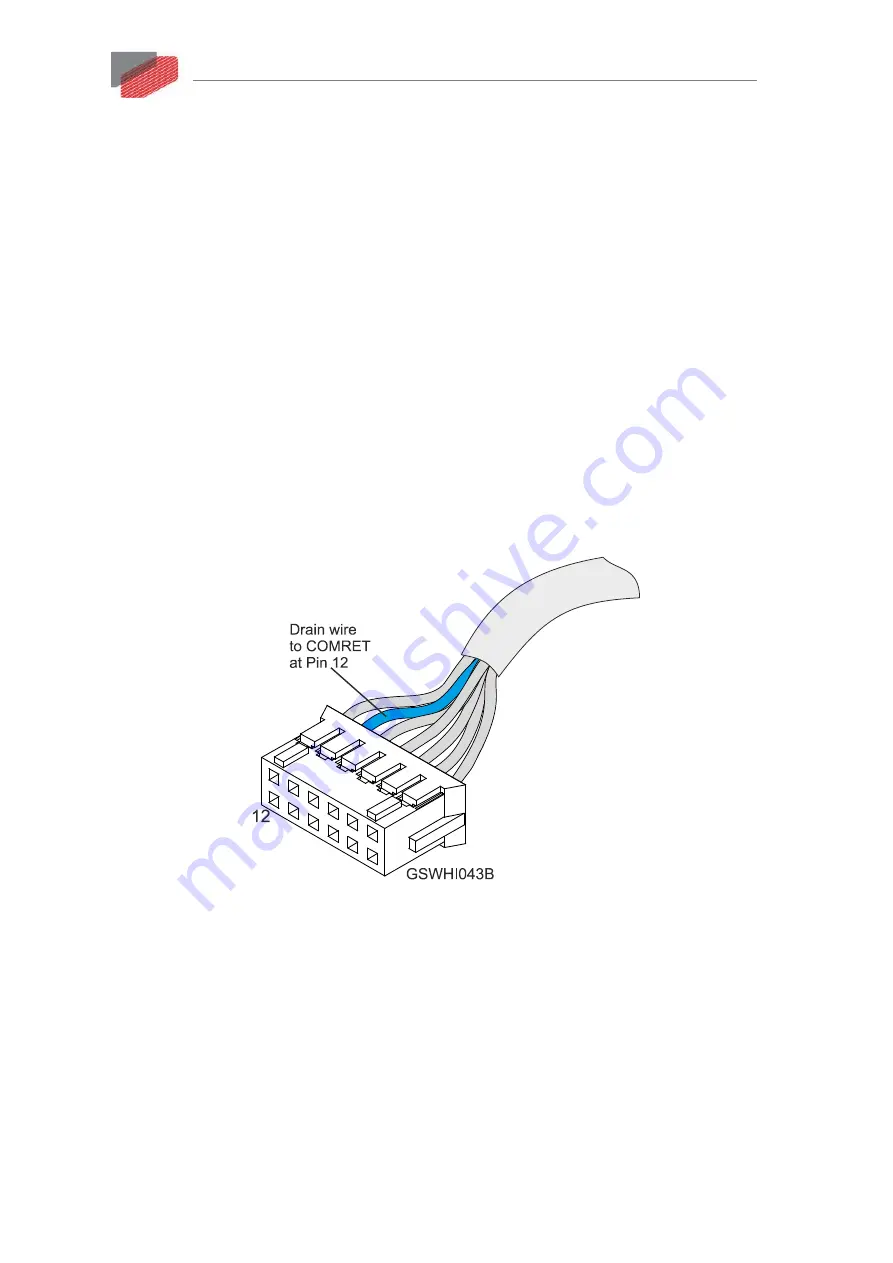

Figure 7: Feedback and Shrouded Control Cable Assemblies – Example

5.

Where there is only one COMRET pin (Common Return) in the connector, which MUST be

connected to the DRAIN WIRE and also to COMRET signal of the cable, it is necessary to

connect the drain wire and COMRET signal to the same pin.