Summary of Contents for 8300 - LEAFLET

Page 1: ...SERVICE MANUAL PARTS LIST MODEL 8300 ...

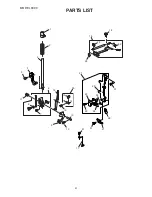

Page 47: ...PARTS LIST 45 MODEL 8300 1 2 3 4 5 6 7 8 9 11 10 6 8 ...

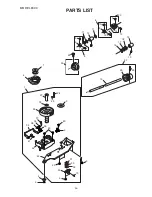

Page 59: ...PARTS LIST 57 MODEL 8300 1 2 3 4 5 6 7 8 13 10 11 12 13 13 14 15 16 17 17 18 19 20 21 22 13 9 ...

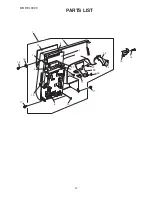

Page 67: ...PARTS LIST 65 MODEL 8300 1 2 3 4 5 6 7 8 8 9 8 10 11 12 13 14 15 16 17 18 19 20 21 ...

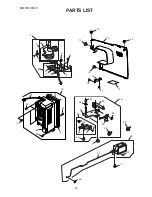

Page 69: ...PARTS LIST 67 MODEL 8300 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 17 18 16 ...