14

MODEL:eXperience 660

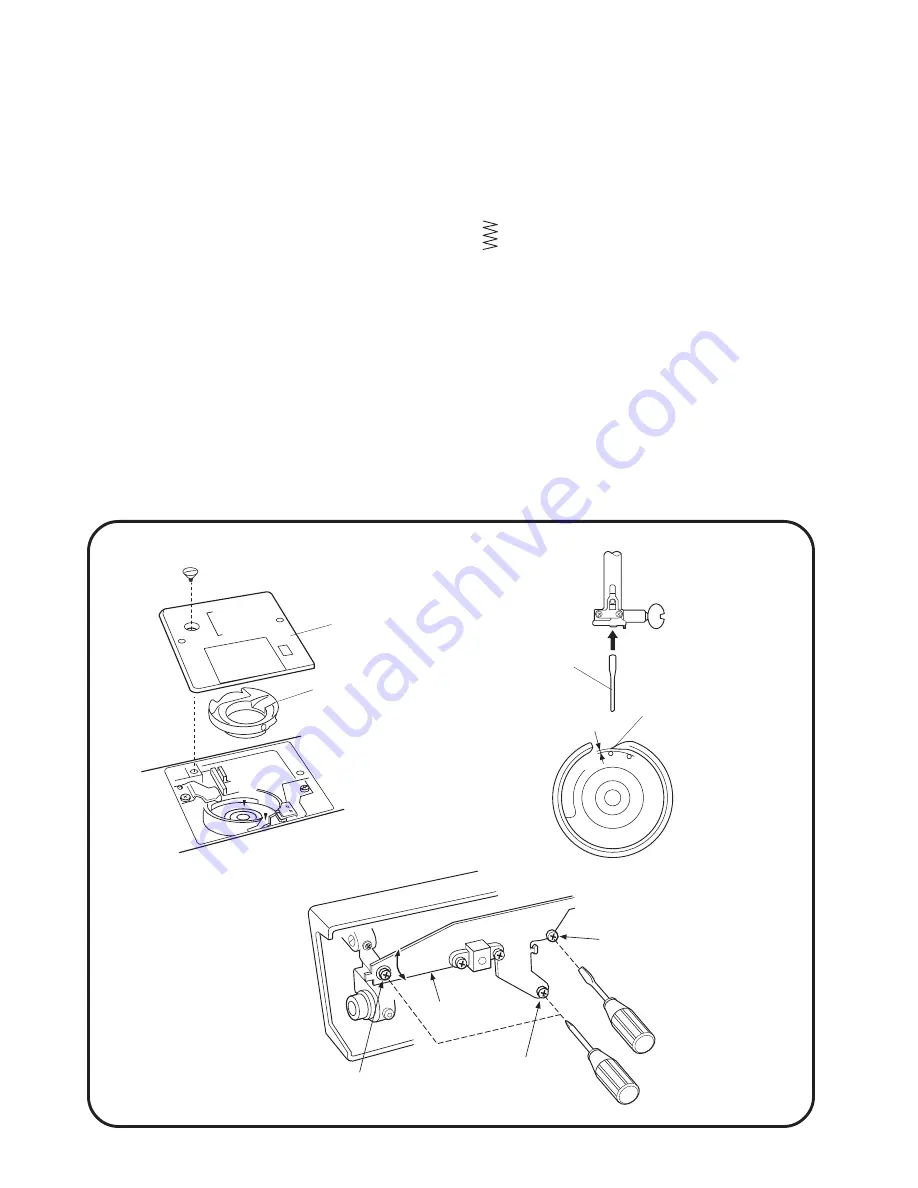

ADJUSTING CLEARANCE BETWEEN NEEDLE

AND HOOK

THE CLEARANCE BETWEEN NEEDLE AND ROTARY HOOK SHOULD BE -0.10 TO +0.05 MM.

1. Turn the power switch on. Select the zigzag stitch " " and set the zigzag width at maximum.

2. Remove the needle plate and bobbin holder. Attach the test pin.

3. Remove the bed cover (see page 7). Loosen the setscrews (A), (B) and slightly loosen the set-

screw (C).

4. Turn the handwheel toward you to bring the tip of the hook behind the test pin and adjust the

clearance between the test pin and the tip of rotary hook to -0.10 to +0.05 by moving the rotary

hook set plate up or down.

5. Tighten the screw (A), (B), (C) firmly.

6. Check the rotary hook driver gear and the lower shaft gear backlash.

If gears mesh or engage tightly or loosely, adjust backlash between hook drive and lower shaft gear.

7. Reattach the bed cover, base needle plate and bobbin holder.

Replace the test pin with the regular needle.

Test pin

-0.1 to + 0.05 mm

Tip of rotary hook

Setscrew (B)

Rotary hook set

plate

Setscrew (A)

Setscrew (C)

Needle plate

Bobbin holder

Shuttle hook gear