User manual & technical documentation– Satellites Decentral – NL-GB-DE-FR-ES-RUS-CZ – Rev 1.1 - 28062017

29

Maintenance

Instruction and training

The owner of the installation is

responsible for the training and

instruction of the maintenance

engineers.

Before maintenance can be

performed on the satellites,

ensure that the installation

is fully depressurised.

Safety conditions for the

maintenance engineers

Safety

•

All safety devices including safety

switches and safety covers must be

properly reinstalled and functioning

normally after maintenance activities

have been carried out.

•

The installation should NEVER be

operated when all or even part of the

safety system has been turned off.

Maintenance

•

The installation may only be

maintained by authorised personnel.

•

The maintenance engineers must be

familiar with the contents of this

technical documentation and be able

to carry out all the instructions given.

Preventive maintenance

•

Regularly check the satellite for leaks

and function. Remedy any leaks

immediately.

•

Regularly check the chemical suction

hose including the injector for

contamination

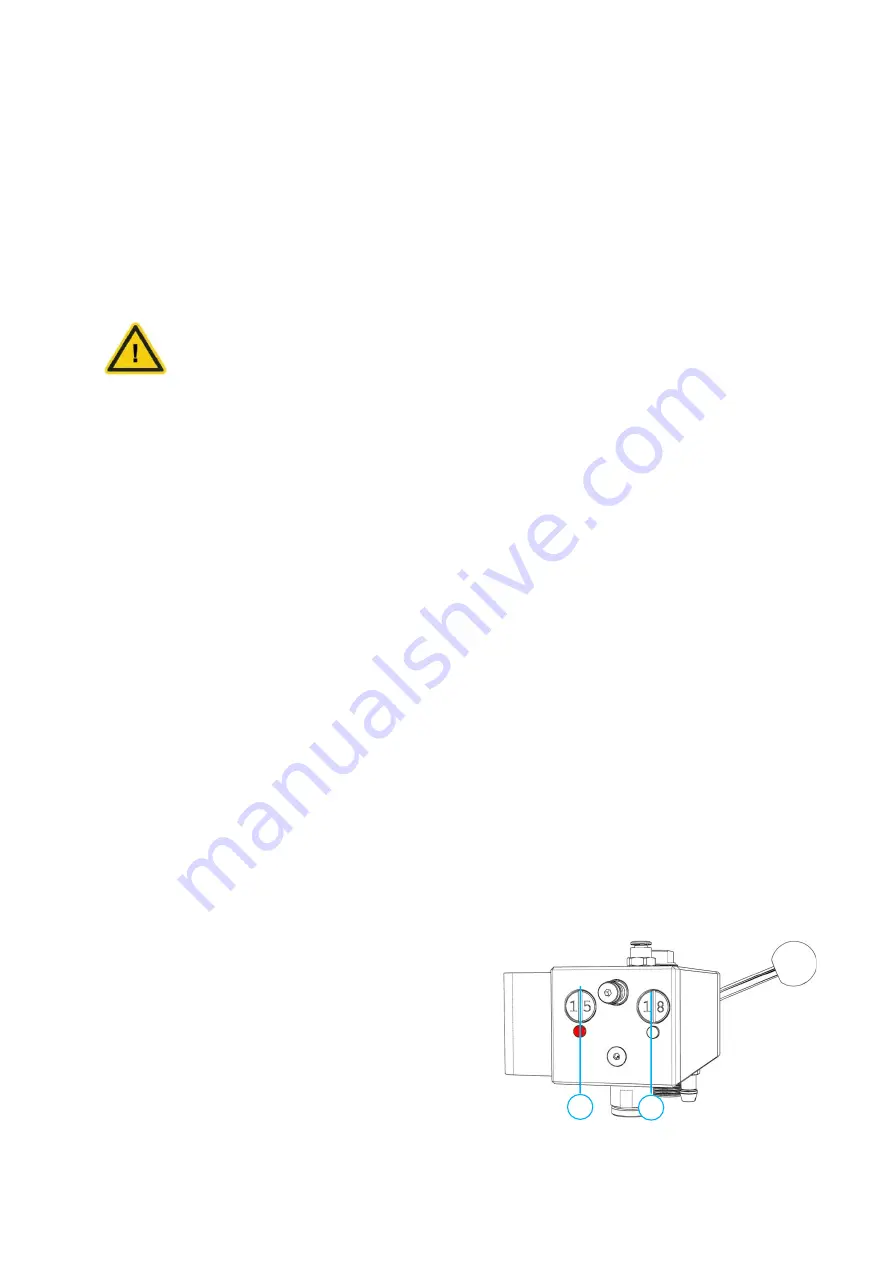

[9]

.

Contamination

influences the operation of the

injector. If the injector does not let

sufficient litres through (for foaming,

± 8.0 litres of water per minute must

flow through the injector), the inside

is probably blocked. Close all valves

of the satellite and depressurise the

hose and optional hose reel by

operating the spray gun until no

more liquid comes out; for this

purpose, disassemble the injector,

which is screwed at left side, with

screwdriver, the white marked

injector is for the foaming liquid and

the red one (only for Blocksat RFD)

for the disinfection liquid. The

injector can now be removed from

the block to be cleaned. Check before

assembly, assure that the O-rings are

undamaged and free from dirt,

grease them with food grease; screw

the injector all the way in until it

stops.

9

9