Al-terminals

(only for crimptool V1311-A)

When crimping Al-terminals of Elpress design the tools below should be used. To choose the correct matrix and

punch, see tooling table below.

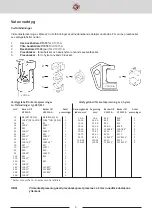

1.

Matrixholder V1320

(not necessary when crimping 185 and 240 mm

2

).

2.

Matrix

(encloses the Al-sleeve and thereby avoiding deformation when crimped).

3.

Punch

(to be crimped down to a stop position, i.e. at a point where the bottom side of the

punch flange halts against the matrix surface).

IMPORTANT! Two compressions are required when crimping Al-terminals. Crimping sequence as per

figure below.

The correct location of the two compressions is determined by the matrix grooves being

locked by a spring-loaded ball in the fork. It is important to check for proper location.

14

Tooling table for indent crimping of Al-terminals

Stranded Solid

Matrix

Punch

mm

2

mm

2

16

16(+25) P13M

P13D

25

35

P13M

P13D

35

50

P20M

P20D

50

70

P20M

P20D

70

95

P20M

P20D

95

120

P25M

P25D

120

150

P25M

P25D

150

185

P25M

P25D

185

240

13P32M*

P32D

240

-

13P32M*

P32D

* Matrix with the prefix 13-- are used without matrixholder.

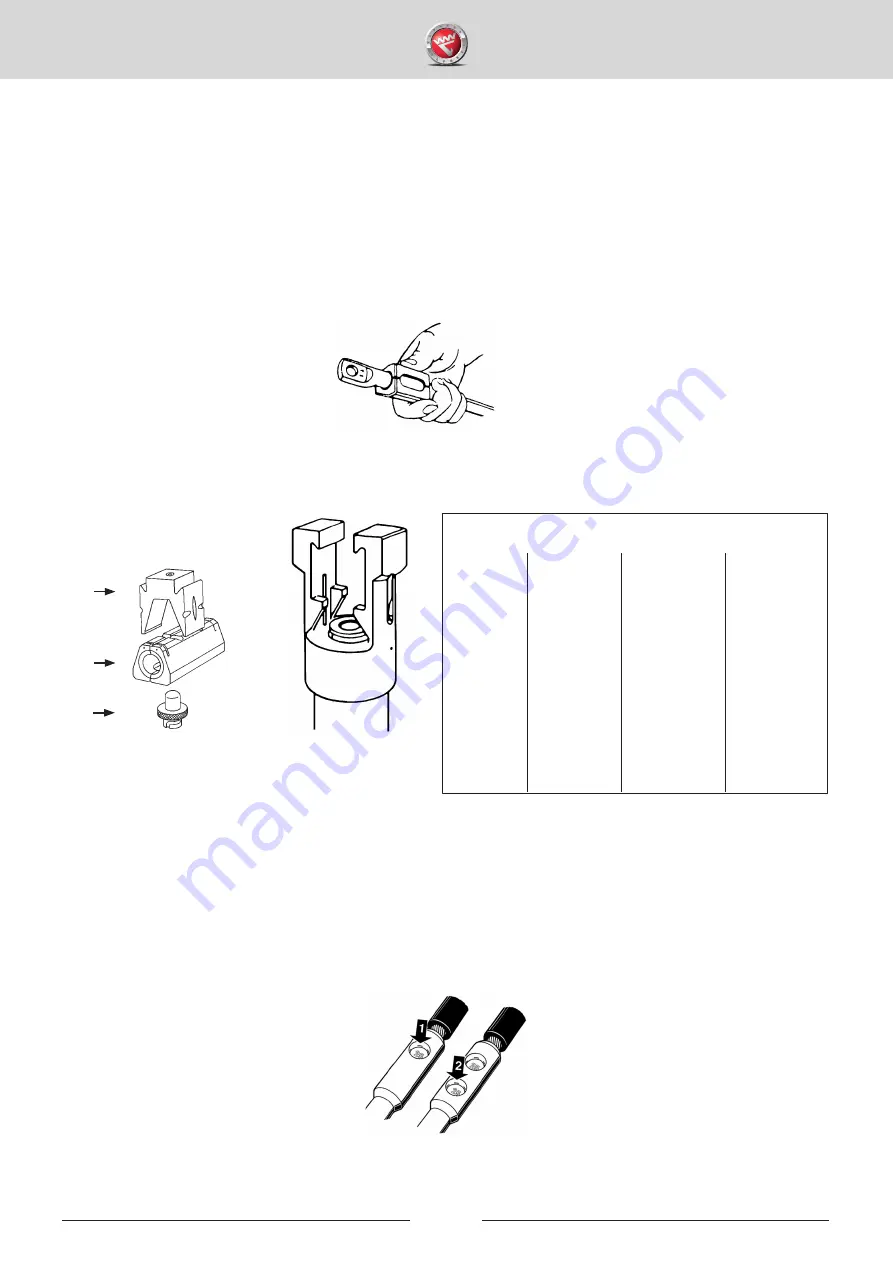

1

2

3

New crimping sequence for

aluminium.

Summary of Contents for V1311-A

Page 27: ......