Technical Manual Cold Storage Controllers TKP / TKC x130 - x140

Page 16

Caution

Communication with VPR systems

The TKx controller can be used as intelligent

cold storage controller in co-operation with the

compound control system VPR. In this case, it is

controlled by the VPR. So the TKx need an individual

address („

adress in netwk

“, mode page)

Each controller can be assigned to a certain

compound (Refrigeration or Freezing, „

com-

pound

“, mode page). This enables the VPR to

transmit specific information to the cold storage

controllers assigned to the compound while a

failure occurs.

More detailed information you will find in the tech-

nical manual of the VPR compound system.

Behavior in case of the VPR-function 'Low Power

Optimization'

If this feature is used in the VPR-system, the VPR

can disable the refrigeration functions of the TKx

for a certain time, even though the refrigeration

setpoint is increased. The fans and the heating

continues working, they will be disabled in case

of compound failure only.

All TKx controllers can be networked together

with other ELREHA-control devices. For this duty

ELREHA has developed E-LINK, a transmission

protocol, which will be transmitted on a two-wire

bus-system based on the RS-485-Standard.

With E-LINK, up to

78

controllers are able to

communicate.

Each controller in a network has its individual

address („

adress in netwk

“, mode page). This

adress is necessary for selecting the right controller

while a data package is transmitted on the network

bus. If the controllers are used outside a network,

the address and the parameter „

compound

“ are

of no importance.

Never use address 64 !!

Remote control with SMZ

The TKx can be remote controlled by a SMZ

frontend. In this case all display information and

keypresses will be transmitted.

Configuration / Service via PC

The controllers can be linked via RS 232 or RS

485 interface to a PC where a matching the EL-

REHA-software runs. From there you can change

parameters, save them to the hard disk (download)

and send it to other controllers (upload).

Networking by RS-485-Bus

(E-LINK-Protocol)

Behavior in case of compound failure

If a TKx is assigned to a certain compound and a

disturbance occurs, the unit responds as follows:

●

The solenoid valves will be closed

●

The fan switches off

●

A defrost cycle will be terminated.

A new defrost cycle is only possible when the

compound problem is solved.

To see if this function is released, look

at „

solenoid valve

“ (actual values page).

Data transmission disturbances

If the controller gets no new information from

the VPR, it continues working with the actual

settings.

If there was an order from the VPR to close the

solenoid valves and a technical defect interupts the

data transmission for more than 30 minutes, the TKx

ignores this order and starts working normally.

When data transmission is restored, the TKx will

work again immediately according to the commands

of the VPR.

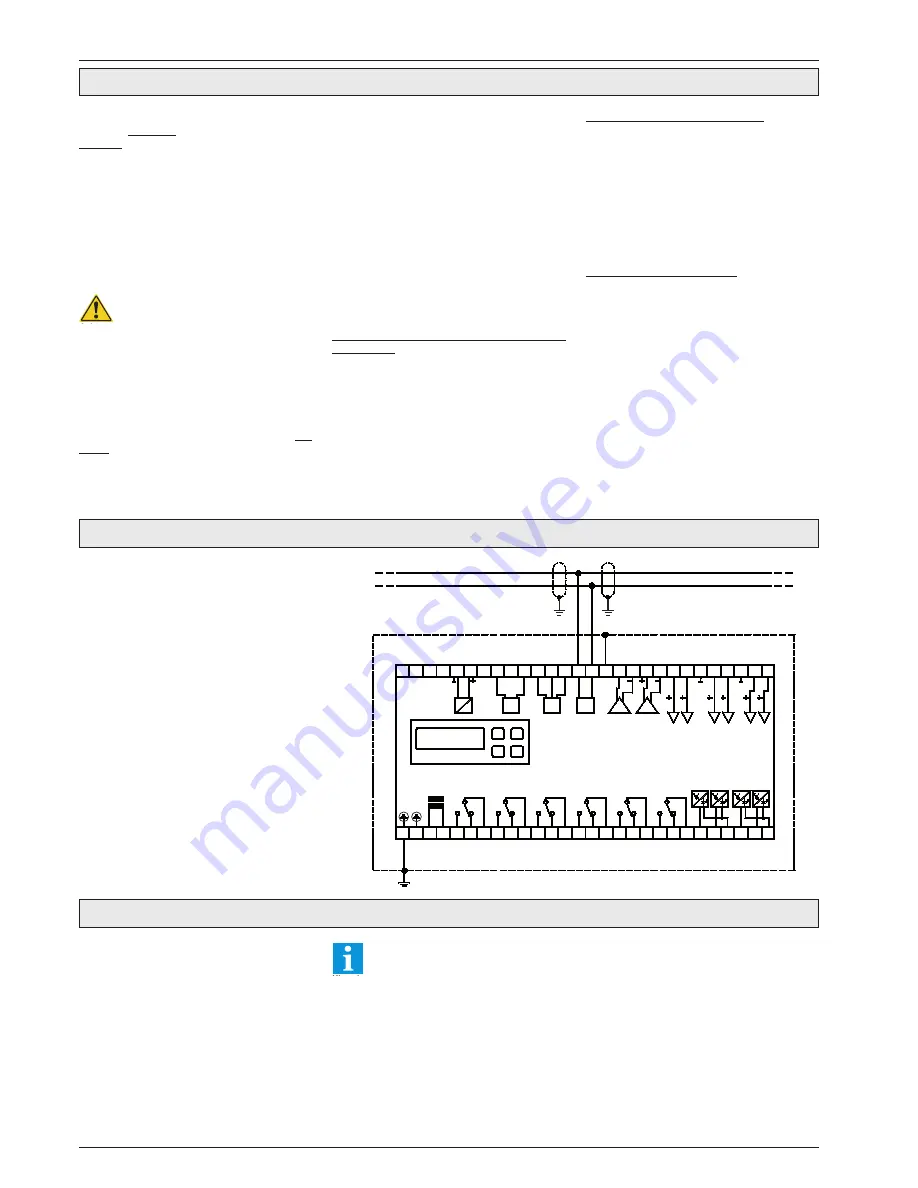

Wiring of data lines

The Line-Interface resp. Line-Bus (RS-485) allows

to connect the controller to a central unit.

Configuration:

●

Use standard "twisted pair" data cable

●

Each module/controller gets an individual

address

●

The best signal-to-noise ratio you get when

each PE connector is grounded the shortest

way

●

The unshielded part of the data cable must be

as short as possible.

The controllers of the TKP 31xx series (from

Soft.Vers. 4.03) are prepared for connecting the

series TAA xx15 Remote Displays.

These displays are able to display the values of

all 6 connectable sensors alternatively.

The TAA display must be connected to the RS-

485-interface "intercom".

Up to 6 TAA xx15 can be connected, each TAA

is able to display any sensor value.

Power Supply

The TAA can be supplied by the TKP-controller

or by an external transformer.

The controllers of the series TKP are

able to supply 2 TAA Remote Displays

max.!

Parameterizing

The TKP controller needs no special settings.

At the TAA the # of the sensor to display must

be set by an incremental switch at the rear side

of the housing.

Display while a defrost cycle

If the controller works in a defrost cycle, the

TAA Remote Display holds the last temperature

value, measured at the beginning of the defrost.

After termination of the defrost event, a real

temperature value will be displayed after the

following preconditions:

●

The measured actual value is less than the

displayed value + 2K

●

After the alarm delay extension is run down

For further information please read the manual

of the used TAA Remote Display.

Connection of Remote Displays

Relais 4

R S

485

Relais 1

1

4

L

3

2

N

5

PE

Netz

TKP 31xx

10

7

6

9

8

14

11

13

12

Relais 2

Relais 3

AC

34

Ve

rso

rg

un

g

un

ge

re

ge

lt

D C

33

38

ND

O

inter-

com

R S

485

DO

35

37

36

OU

T

DO

GN

D

R S

232

IN

42

41

40

39

4..

.20

mA

Au

sg

an

g

0..

.10

V

Au

sg

an

g

Schaltschrank / Electrical Cabinet

OK

1

23

18

15

17

16

19

21

20

22

Relais 5

Relais 6

27

25

24

26

28

OK

4

OK

2

OK

3

51

ND

O

43

46

45

44

F

5

F

6

47

49

48

50

F

1

55

F

3

F

4

F

2

54

53

52

56

Notice