ELSEMA

MD240-2 Vehicle Loop Detector

- 9 -

Detector position and installation

Install the detector in a weatherproof housing.

The detector should be as close to the sensing loop as possible.

The detector should always be installed away from strong magnetic fields.

Avoid running high voltage wires near the loop detectors.

Do not install the detector on vibrating objects.

When the control box is installed within 10 metres of the loop, normal wires can be used to connect the

control box to the loop. More than 10 metres requires the use of a 2 core shielded cable. Do not exceed

30 metres distance between control box and loop.

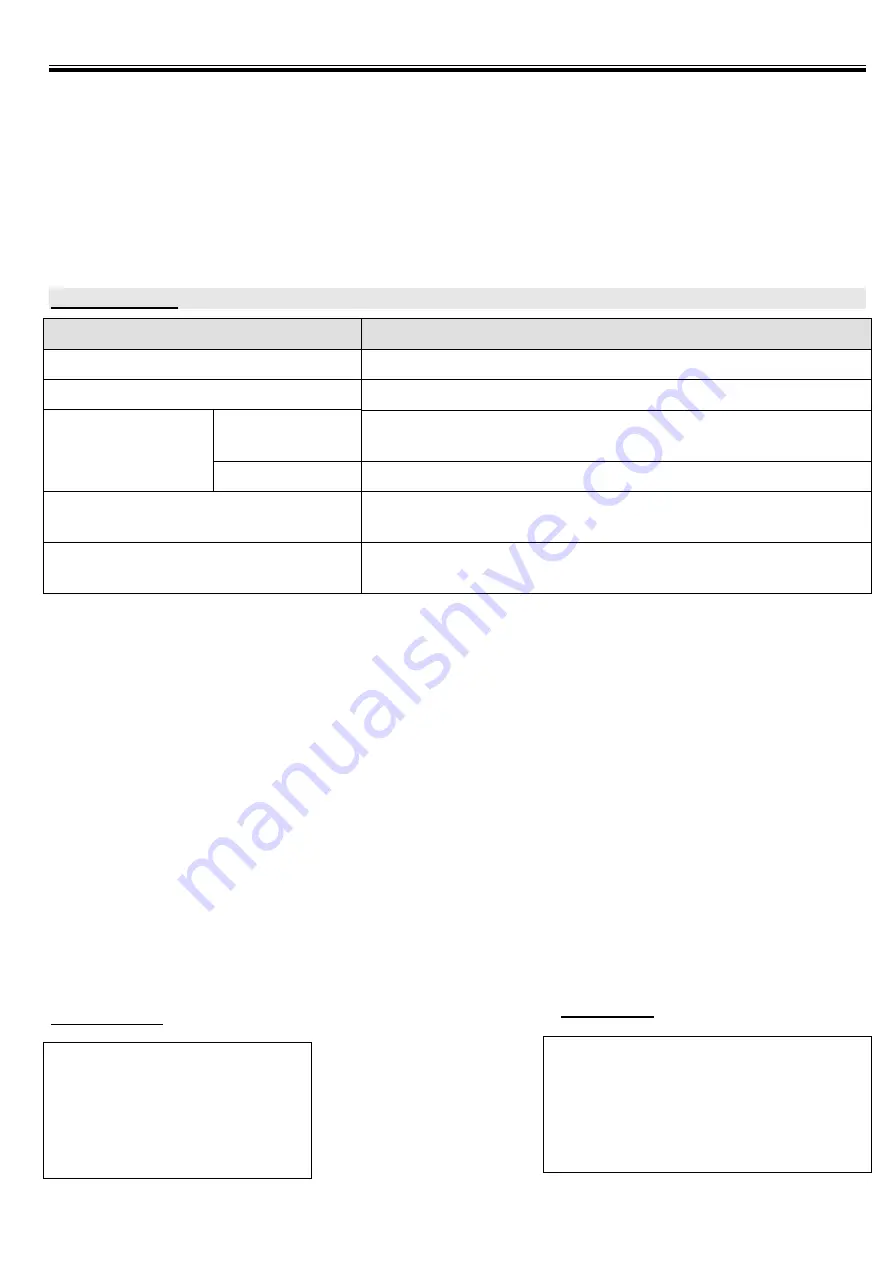

Troubleshooting

Symptoms

Solution

If the detector is not working

Press reset

If red led indicator is not fully lit

Check for power supply

If green led

indicator:

Blinks slowly

It maybe because the loop is short circuit or the no: of turns is not

enough.

Blinks faster

It maybe because the loop is open or the no: of turns is too many.

If no: of turns is not enough

Lower the frequency (if the frequency is still too high, you must add

more turns).

If no: of turns is too many

Higher the frequency (if the frequency is still too low, you must

remove some turns).

Manufactured by

Elsema Pty Ltd

31 Tarlington Place

,

Smithfield

NSW 2164, Australia

Ph: 02 9609 4668

Fax: 02 9725 2663

Website: http://www.elsema.com

Distributed by