8

Installation and start-up

Sensor Sewi KNX TH-L-Pr

• Version: 17.11.2016 • Technical changes and errors excepted.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

2.2. Installation location

Install and use only in dry interior rooms!

Avoid condensation.

The

Sensor Sewi KNX TH-L-Pr

is installed surface mounted on walls or ceilings.

For

capturing movement

make sure that the desired area is covered by the sensor's

coverage angle and that no obstacles obstruct the recording.

When selecting an installation location, please ensure that the measurement results of

temperature and humidity

are affected as little as possible by external influences.

Possible sources of interference include:

•

Direct sunlight

•

Drafts from windows and doors

•

Draughts from ducts coming from other rooms or the outdoors

•

Warming or cooling of the building structure on which the sensor is mounted,

e.g. due to sunlight, heating or cold water pipes

•

Connection lines and empty ducts which lead from warmer or colder areas to

the sensor

Measurement variations from such sources of interference must be corrected in the

ETS in order to ensure the specified accuracy of the sensor (offset).

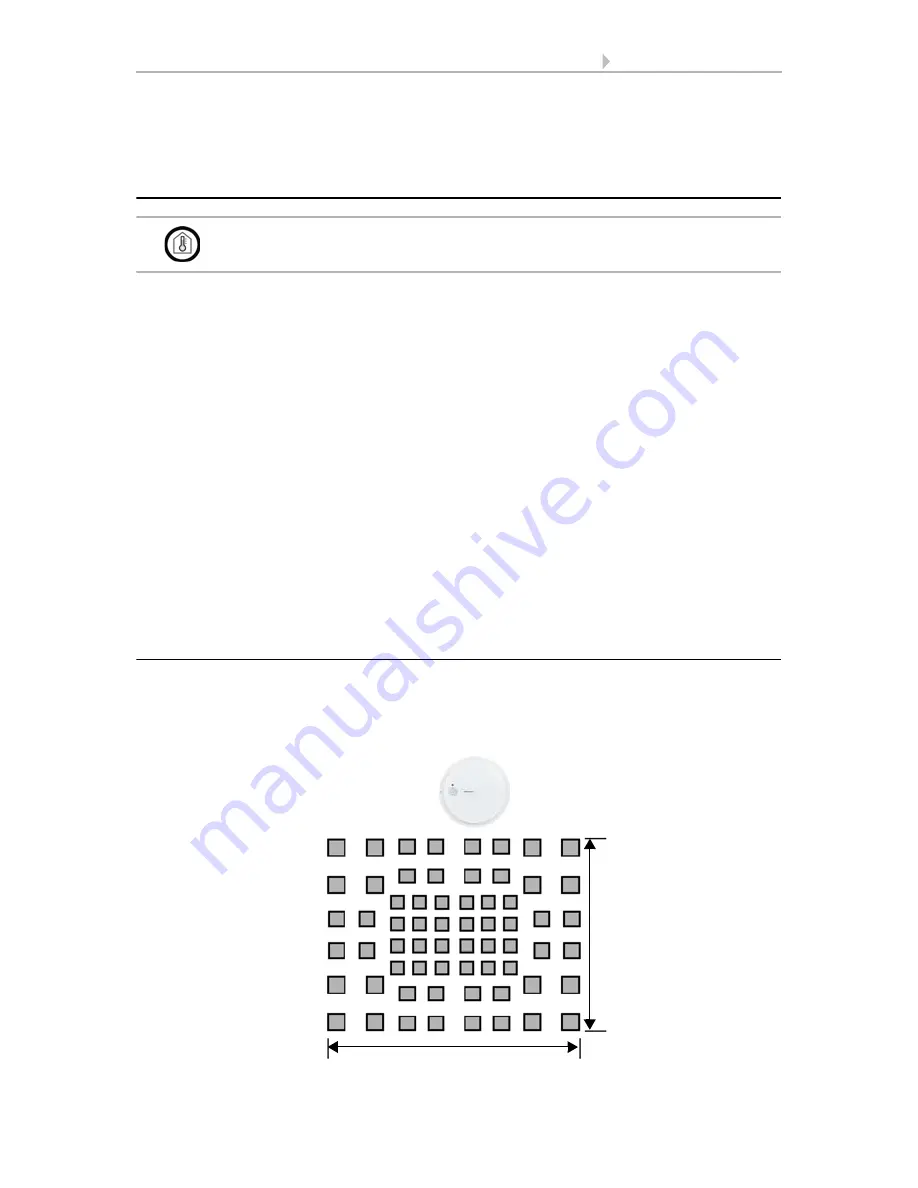

2.2.1. Coverage area of the motion detector

Angle of coverage: approx. 100° × 82°

Range: approx. 5 m

Segmentation of the coverage area

Fig. 1

Distance 2.50 m

5.

66

m

7.42 m