Model 2000 Flow Computer Instruction Manual

APPENDIX 3 GAS CHROMATOGRAPHS SUPPORTED

Model 2000 issue 21

Page No

85

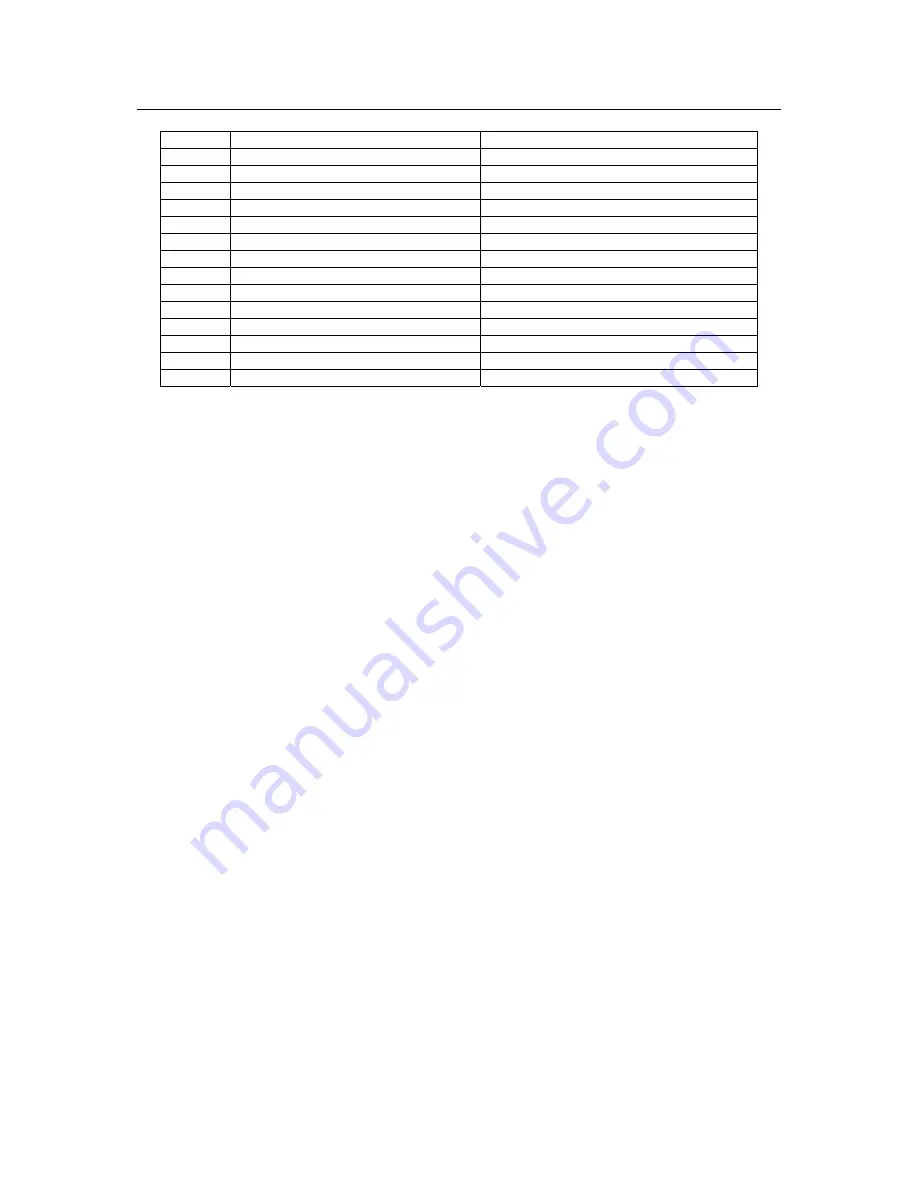

7#10

Component Number 11

Default iC5

7#11

Component Number 12

Default nC5

7#12

Component Number 13

Default nC6

7#13

Component Number 14

Default nC7

7#14

Component Number 15

Default nC8

7#15

Component Number 16

Default nC9

7#16

Component Number 17

Default nC10

7#17

Component Number 18

Default Hs

7#18

Component Number 19

Default rd

7#19

Component Number 20

Default Not Used

7#20

Component Number 21

Default Wobbe S

7#21

Component Number 22

Default Hi

7#22

Component Number 23

Default Wobbe i

7#23

Component Number 24

Default Not Used

7#24

Stream alarm

Stream alarm register

Additional response factor information is read from addresses 7054 - 7070 for new response factors. Addresses 7071 - 7087

for current response factors, and addresses 7088 - 7104 for the initial response factors.

The stream alarm can be configured to display either non-accountable alarms, accountable alarms or both for each of the

available 32 bits of data.

Summary of Contents for 2000

Page 3: ...Model 2000 issue 21 Page No 3 ...

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......