GB-3

D

GB

F

NL

I

E

Enclosed documentation (flow rate curves, op-

erating characteristic diagrams, dimension sheet,

spare parts list, spare parts drawing and Declara-

tion of Incorporation)

Type label

Maximum burner capacity, gas type – see type label.

type

ECOMAX

nom capacity

kW

fuel

Installation

CAUTION

We recommend that lifting gear be used for instal-

lation due to the weight involved.

▷

With the ECOMAX

®

..C, the air guide tube is sup-

plied separately to prevent transport damage

or is fitted with extra transport protection. See

attached documentation.

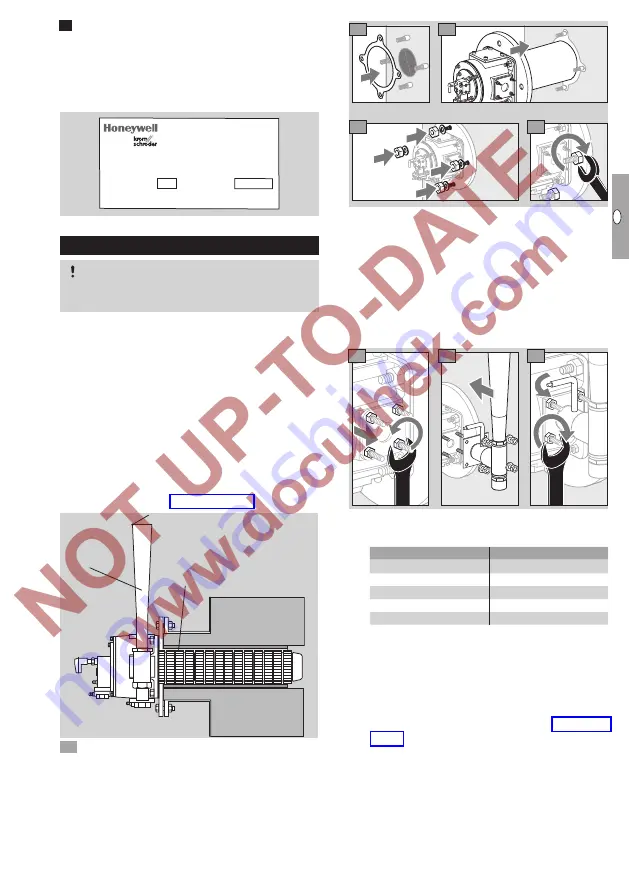

Installation on the furnace

▷

The burner has three connectors for air and one

for flue gas. During installation, the burner must

be aligned appropriately (flue gas upwards or

to the side).

ECOMAX

®

for direct heating systems

▷

For a direct heating system, the flue gas guide

tube FGT-Set..D and the eductor EJEK are re-

quired, see page 14 (Accessories).

EJEK

FGT-Set..D

Remove the transport safety device.

▷

If the diameter of the furnace insulation is greater

than the outside diameter of the flue gas guide

tube, wrap the flue gas guide tube with a fibre

blanket before installing the burner.

3

4

2

5

▷

Tighten the nuts in two cycles in a crosswise

fashion, torque: 46 Nm.

▷

When installing, always ensure that when the

burner is mounted, it is sealed tightly on the

furnace.

Installing the eductor

▷

The eductor is mounted to the side of the burner.

▷

Align the eductor’s pressure test point to the

control side.

1

3

2

▷

Use the correct torque so that the housing is

not damaged.

Type

Torque

ECOMAX

®

1

26 Nm

ECOMAX

®

2

26 Nm

ECOMAX

®

3

30 Nm

ECOMAX

®

4

35 Nm

ECOMAX

®

5

35 Nm

▷

After installing the eductor, connect the

ECOMAX

®

to the air and gas circuits.

ECOMAX

®

for indirect heating systems

▷

For an indirect heating system, the ra-

diant tube SER, the segmented flame

tubes SICAFLEX

®

and

the flue gas connec-

tor FLUP are required, see page 14 (Acces-

sories).