GB-7

D

GB

F

NL

I

E

DANGER

Risk of explosion! Fill the gas line to the burner

carefully and correctly with gas and vent it safely

into the open air – do not discharge the test volume

into the furnace chamber.

Determining the gas and combustion air flow

rates

Q

Gas

= P

B

/H

u

Q

Luft

= Q

Gas

.

λ

. L

min

▷

Q

Gas

: Gas flow rate in m

3

/h (ft

3

/h)

▷

P

B

: Burner capacity in kW (BTU/h)

▷

H

u

: Gas calorific value in kWh/m

3

(BTU/ft

3

)

▷

Q

Luft

: Air flow rate in m

3

(n)/h (SCFH)

▷

λ

: Lambda, air index

▷

L

min

: Minimum air requirement in m

3

(n)/m

3

(n)

(SCF/SCF)

▷

Information on the gas quality supplied can be

obtained from the competent gas supply com-

pany.

Common gas qualities

Gas type

Lower calorific value

L

min

m

3

(n)/m

3

(n)

(SCF/SCF)

kWh/m

3

(n) (BTU/SCF)

Natural

gas H

11

1114

10.6

Natural

gas L

8.9

901

8.6

Propane

25.9

2568

24.4

Town gas

4.09

425

3.67

Butane

34.4

3406

32.3

▷

Data in kWh/m

3

(n) refer to the lower calorific

value H

u

and data in BTU/SCF refer to the upper

calorific value H

o

.

▷

A minimum air excess of 20% (lambda = 1.2)

should be set in a cold furnace for initial adjust-

ment since the air volume falls as the tempera-

ture rises.

▷

Fine adjustment should be carried out at max.

furnace temperature and at as high a capacity

demand as possible.

Notes on the flow rate curve

▷

If the gas density in the operating state differs

from that reflected in the flow rate curve, convert

the pressures according to the local operating

state.

p

B

= p

M

.

δ

B

δ

M

▷

δ

M

: Gas density reflected in the flow rate curve

[kg/m

3

(lb/ft

3

)]

▷

δ

B

: Gas density in operating state [kg/m

3

(lb/ft

3

)]

▷

p

M

: Gas pressure reflected in the flow rate curve

▷

p

B

: Gas pressure in operating state

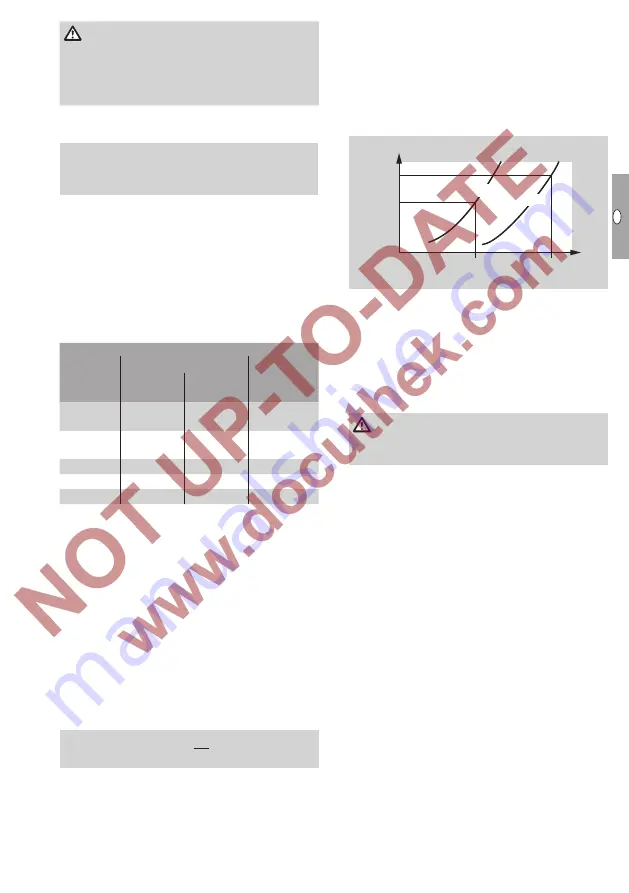

Determining the gas and combustion air

settings

▷

Orifices are installed in the gas and combustion

air connections on the burner.

▷

Adjustment is made on the basis of the flow rate-

dependent pressure differential. The required

pressure differentials for gas and air are shown

in the burner diagram.

[mbar ("WC)]

[m

3

/h (ft

3

/h)]

Q

gas

∆p

air

∆p

gas

Q

air

∆p

gas

∆p

air

▷

Ensure an undisturbed flow to the orifice. We

recommend that a double nipple to ISO 65 with a

length of at least 5d be inserted into the connec-

tion. If pipe elbows and angles, reducing fittings,

couplings, etc. are used in the immediate vicinity

of the burner connection, differences from the

flow rate curves will occur which may result in

incorrect burner settings.

WARNING

Incorrect burner settings may result in substoichio-

metric burner operation.

Notes on motive air at the eductor

▷

The motive air is set at the eductor by measur-

ing the negative flue gas pressure p

FG

between

the burner and eductor. The required negative

pressure is shown in the eductor diagram, see

www.docuthek.com, on the basis of the maxi-

mum furnace temperature and burner capacity.

▷

With 80% flue gas extraction, a low furnace pres-

sure (0.1 to 0.3 mbar) can normally be main-

tained in direct heating systems. Initial adjust-

ment with a cold furnace should be made with

a reduced extraction rate. This avoids infiltrated

air caused by a negative pressure in the furnace

which would falsify the flue gas measurement.

▷

During the commissioning procedure, the motive

air setting must be optimized (maximize flue gas

extraction). The furnace pressure must remain

slightly positive in all operating states (0.1 to

0.3 mbar).

If the positive pressure exceeds approx. 0.3 mbar,

increase the flue gas extraction rate to prevent

the burner being damaged.

If there is a negative pressure in the furnace

chamber, reduce the flue gas extraction rate to

avoid infiltrated air.