Chapter 4

Troubleshooting

Yes

The safety system for the heater does not have the correct initial setup.

Check that the flap for the sail switch is not stuck in the open position. If the sail

switch is not physically stuck open, check that the resistance across the sail

switch is above 1 MΩ when the heater is off. If the resistance is below this valve,

the sail switch needs replacement.

Problem: Fan Runs But Heater Fails to Ignite

With the gas off, start the heater by turning up the thermostat to the maximum temperature. The

red light should turn on a couple seconds after the fan starts and you should hear a faint clicking

noise fifteen to thirty seconds after the blower starts. If you do, then:

Rule out general problems.

Carefully check the fuel system. Check that the propane

tanks contain fuel, all gas lines are undamaged, and all fittings are tight. Check the

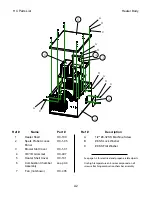

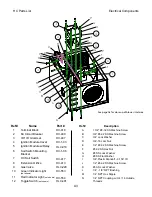

connections at the thermostat for problems. Remove the cover of the heater and check the

wiring for damage or loose connections and the components in the heater for obvious

damage. Check that the heater is getting at least 12 VDC.

Inspect the spark ignition system

. The spark ignition system should create one spark

across the tip of the spark probe in the combustion chamber on each faint click. The spark

can be in an incorrect location for any of the following reasons: damage to the spark

probe wire, loose connections, and deposits on the spark probe. To access the spark probe

to check it for deposits, removing the access panel on the side of the heater by the

combustion chamber. The metal tips of the spark probe should only be slightly rounded

with an 1/8” gap at the tip. In addition, the insulator on the probe should have no cracks

or chips missing and only have light deposits on the insulator. If the spark probe is

damaged or excessively round, it should be replaced. If the spark probes only has

deposits, carefully remove them with a damp rag or abrasive plastic pad.

The small blower may not be working.

With the gas off, check that air is flowing

though the combustion chamber and that the small blower is turning. If it is not working,

check for loose connections or obstructions or damage to the blower. If you find nothing

obvious, remove the blower and test it at 12 VDC to see if it is functioning correctly.

If the red light does not come one and you don't hear the faint clicking noise then

The sail switch or high temperature switch may be malfunctioning

. If the sail switch

fails to close or the high temperature switch is stuck open the heater will not attempt to

ignite. Also loose or damaged wire to either of these items will cause the same problems.

Check the wiring to these two items. With the power off to the heater, use a multimeter to

check that the resistance of the the high temperature switch is less than 1 ohm. If it is

higher, it should be replaced. Also, check if the sail switch closes when the heater runs by

disconnecting the wiring to the sail switch and checking if the resistance drops to zero

when the fan is running. If the wiring and two switches check out ok, refer to the

troubleshooting tips above for this problem.

If the red light comes on but you don't hear the faint clicking noise then

This indicates either a short in high voltage line or a malfunctioning ignition

module

. Check the high voltage line for damage. If no problems are found, remove the

high voltage wire from the spark probe on the combustion chamber (it can be accessed by

removing the access panel on the side of the heater by the combustion chamber). With the

9