Chapter 6

Repair

Repair

6.1 Performing a Full Adjustment of the Burner

Tools required: Phillips screwdriver, two needlenose or similar pliers, wrench set ,

socket set (optional), pipe dope or sealant

1) Turn off power and gas to the heater.

2) Remove the cover to the combustion chamber by removing the four nuts holding

it.

3) Remove the gas fittings attached to the burner.

4) Remove the spark electrode on the bottom of the burner.

5) Remove the burner from the combustion chamber by removing the bolt that holds

it in place.

6) Blow out the combustion chamber and the burner with compressed air. Clean any

more stubborn deposit off of the burner. Since removal of the combustion

chamber and burner is rarely necessary it is

not unusual to see modest deposits inside

the heater.

7) Reinstall the spark electrodes from the

bottom of the burner

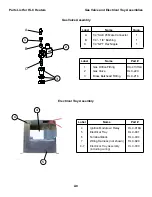

8) Check that the gap between the two spark

electrodes shown in Figure 8. If the gap is

larger that 1/8” then adjust the gap to the

correct width. Use care when making

adjustments as the insulator is fragile.

9) Reinstall the burner into the combustion

chamber.

6.2 Checking the Operating Voltage of the Heater

Tools required: Phillips screwdriver and a multimeter

1) Turn off power to the heater at the control box using the rocker

switch.

2) Remove the cover to the thermostat shown in the Figure 9.

3) With a multimeter set to VDC, check the voltage between one

of the brass screws on the thermostat and the electrical tray.

Refer to the troubleshooting guide for correct range of voltages.

23

Figure 8: Spark Gap

Figure 9:

Thermostat