CONTROLLER

TEMPERATURE

LOW

ALARM

LED

x1

x10

x100

5

2

1

LIMITER

TEMPERATURE

HIGH

ALARM/

RESET

12

www.eltherm.com

12

Operating instructions

Ex – Temperature Controller Ex-TC/…-It

BU 122-It

Revision 2

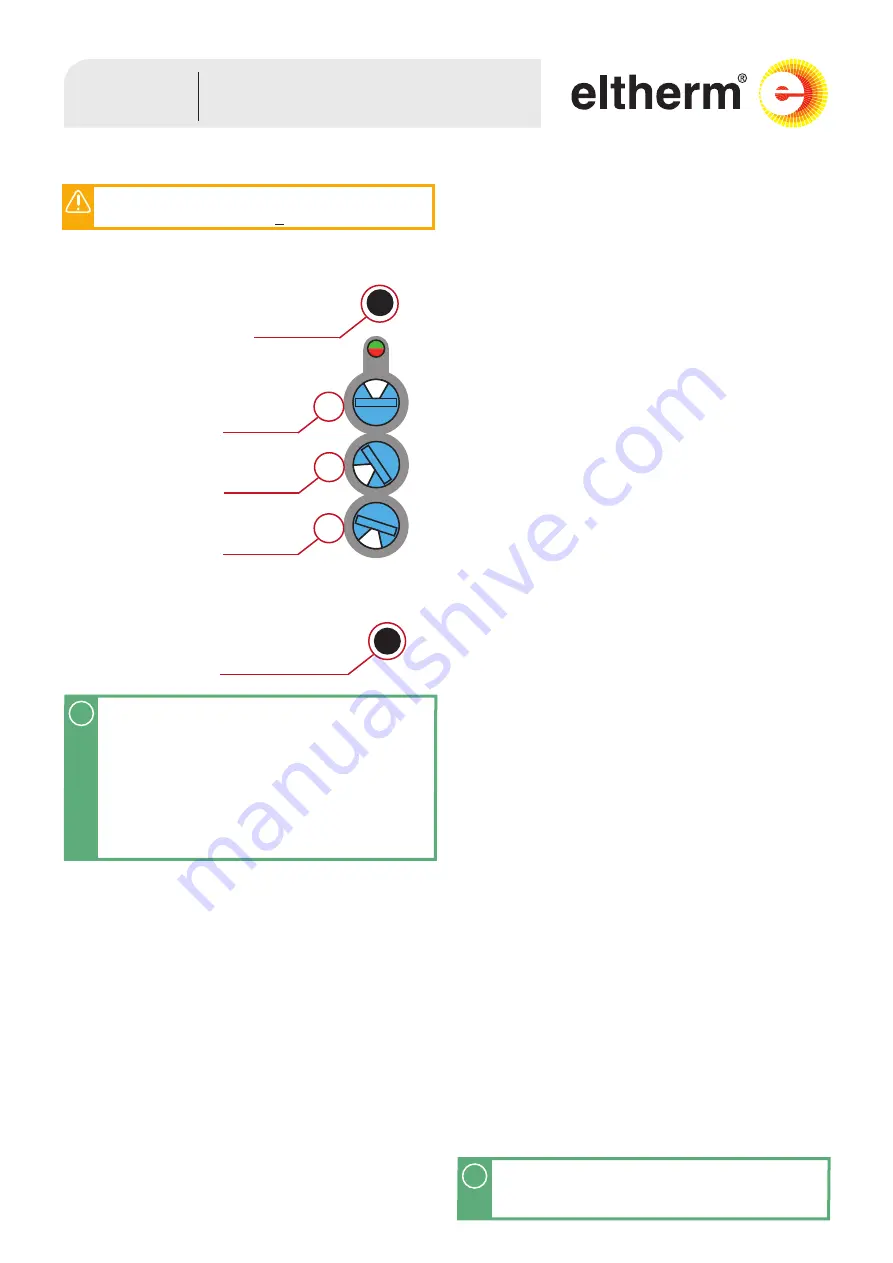

ALARM & SETPOINT SETTINGS

ATTENTION

Theoretical setting range 999°C.

Max. permitted setting range < 450°C!

Controller reset

button

Setting example

(all models)

Ones

Tens

Hundreds

e.g. 125°C

Limiter reset

button

First set the limiters (alarm values), then the controllers

(setpoints).

When powering on, switch the limiters in the

Ex-TC/

AL

devices to “on” if there are no errors present

and the

ACTUAL

temperature is below the

limiter

SETPOINT

values.

NOTE

i

Factory setting: 5°C

After the alarm settings have been completed, set the tem-

perature setpoint. Use the blue rotary knobs of the controller

to select the desired setpoint.

The selected value can be seen in a recess at the edge of the

rotary knob. Values outside of the setting range (> 450) will be

indicated by a flashing LED alternating between

green

and

red

. Temperature control remains inactive for this time.

Factory setting:

0

°C

After the alarm settings have been completed, set the maxi-

mum temperature for the limiter.

The selected value can be seen in a recess at the edge of the

rotary knob.

Factory setting:

0

°C

Press the

reset button of the limiter and hold it until the LED

flashes

green

.

Set the desired upper temperature limit with the blue rotary

knobs of the controller

The selected value can be seen in a recess at the edge of the

rotary knob.

To confirm press the reset button until the LED goes out.

Then the desired temperature setpoint must be set again.

•

After 100 seconds the setting menu closes

automatically without any values being saved.

Setting the temperature setpoint (

Ex-TC/It-A, -AL

and

-M

)

Setting the maximum temperature (

Ex-TC/It-AL

)

Setting the overtemperature alarm (

Ex-TC/It-AL

)

Factory setting:

0

°C

Press and hold the reset button of the controller until the LED

flashes green. Set the desired upper temperature limit with

the blue rotary knobs of the controller (labelled with CON-

TROLLER TEMPERATURE).

The selected value can be seen in a recess at the edge of the

rotary knob.

To confirm press the reset button (

LOW ALARM

) until the LED

goes out.

•

After 100 seconds the setting menu closes

automatically without any values being saved.

Then the desired temperature setpoint must be set again.

Setting the undertemperature alarm

(

Ex-TC/It-A

,

-AL and -M

)

•

Disconnect the Ex-TC/M from the power supply

•

Set the temperature adjustment buttons to 9 9 9 and

connect Ex-TC/M to the power supply -> LED flashes

green

quickly

•

Set the Modbus address with the temperature setting

buttons (hundreds / tens / ones)

•

Confirm the setting with the reset button -> LED flashes

more slowly and is then lit continuously.

•

Disconnect the Ex-TC/M from the power supply

•

Connect the Ex-TC/M to the power supply, set the tem-

perature setpoint and place the device in operation.

MODBUS SETTINGS

(Ex-TC/It-M)

Make note of the settings

made on page 14.

NOTE

i