13

www.eltherm.com

13

www.eltherm.com

The following value are transferred by bus:

1.

Data word

Controller

IS

value,

HI

,

LO

2.

Data word

Controller

REF

value,

HI

,

LO

3.

Data word

Controller

Undertemperature alarm

value

,

HI

,

LO

4.

Data word

Controller error

Sensor error

0x01

0000 0001

Undertemperature alarm

0x02

0000 0010

Measuring range error

0x04

0000 0100

MODBUS SETTINGS

(Ex-TC/It-M)

SUPPORTED MODBUS PROTOCOL FUNCTIONS

Code MODBUS function Register

Action

03h

READ HOLDING

REGISTERS

4xxxx

Read setpoints and error

messages from control-

lers and limiters

08h

DIAGNOSTIC

Function test of slaves

10h

WRITE MULTIPLE

REGISTERS

4xxxx

Send setpoints

to controllers

and limiters

MODBUS PARAMETERS

MASTER-SLAVE application

Ex-TC/M

Interface

RS485

Format

RTU

Start bit

1

Data bit

8

Stop bit

1

Transmission rate

9600 baud

Parity

None-parity

Slave ID

1...120

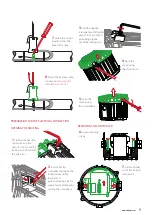

COMPLETING THE INSTALLATION

CLOSING THE HOUSING

1

Visual inspection of housing and cover to ensure they are

not damaged. Cover can only be inserted in one position

(locking arms / twist protection recesses have different

width). Move the cover to the appropriate position.

2

Attach the cover with the narrower locking arm (without a

headless screw), close the cover

and…

3

Use the pliers to lock the cover

OPERATION & MAINTENANCE

•

Observe the locally applicable safety regulations when the Ex-

TC is in operation

•

Comply with the permitted operating conditions in accordance

with the “

TECHNICAL DATA

” section and the labelling . (type/

dimensions of lines, pipe diameter, operating conditions,

IP

protection type).

DANGER

•

If the temperature setpoint needs to be checked,

first make certain that there is no explosive atmos-

phere present and that none can occur.

•

Then connect the power supply and open the

housing cover.

•

Instead of the Pt100 sensor, connect a Pt100

simulator and check the switching function of the

controller.

•

After the check is complete, reconnect the Pt100

sensor and close the cover.

WARNING

The junction box may only be

opened (this also includes loosening cable entries!)

when it is disconnected from the power supply.