The teeth of a new blade are very sharp

and can be dangerous.

Clamping the workpiece in position

(fig. D, E, F, G, L, M & N)

Your Elu toothed chopsaw is equipped with a

material clamp (6).

• Pull the lever (19) toward the handle (20) (fig. D).

• Push the clamp shaft (21) forward until the jaw

(22) is almost touching the workpiece.

• Press the lever (19) toward the jaw (22) until it

engages with the clamp shaft (21).

• Rotate the handle (20) clockwise and clamp the

workpiece securely.

• To release the workpiece, rotate the handle (20)

counterclockwise.

• Support long workpieces using a piece

of wood (23) (fig. E). Do not clamp the

cut off end (24).

• Always attempt to clamp the workpiece

in a way to minimize the number of teeth

cutting through the material (fig. L).

• Clamp the workpiece as far towards the

operator as possible.

• Set the clamping position for cutting

downstroke as long as the thickness of the

workpiece is not exceeding the maximum

downstroke cutting capacity (fig. M).

- The maximum downstroke cutting

capacity is marked by slot (31).

- Continue setting the clamping position

as described below.

Vertical clamp (fig. F & G)

The vertical clamp (25) is used for upstroke cutting

of wide and irregular shaped materials (fig. F).

• Insert the vertical clamp (25) in one of the holes

(26) (fig. G) in the base until the clamp rests on

the workpiece.

• Pull the lever (27) down to clamp the workpiece

(fig. F).

• Lift the lever (27) to release the clamp (25).

Always use the vertical clamp when

cutting upstroke.

20

en - 5

E N G L I S H

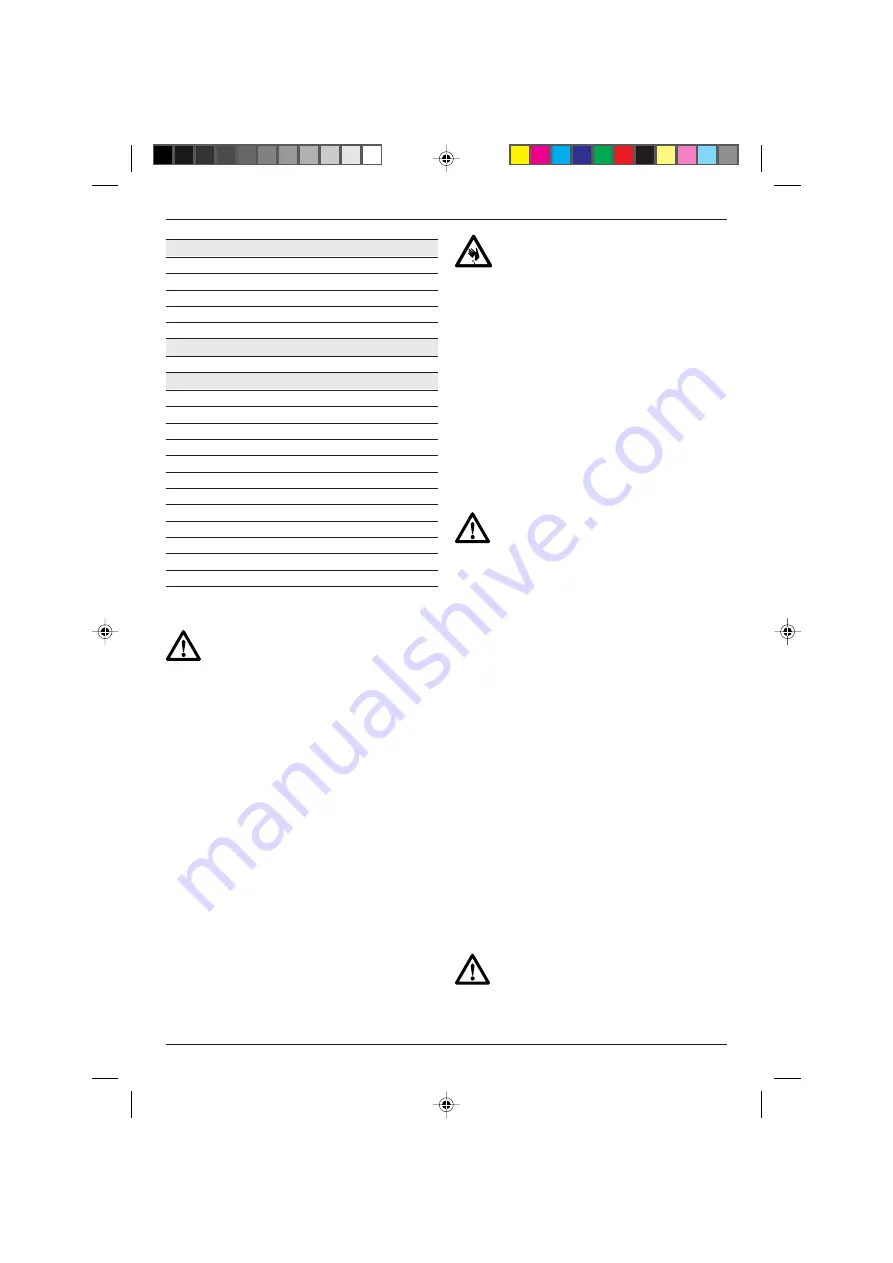

Conductor size (mm

2

)

Cable rating (Amperes)

0.75

6

1.00

10

1.50

15

2.50

20

4.00

25

Cable length (m)

7.5

15

25

30

45

60

Voltage

Amperes

Cable rating (Amperes)

115

0 - 2.0

6

6

6

6

6

10

2.1 - 3.4

6

6

6

6

15

15

3.5 - 5.0

6

6

10

15

20

20

5.1 - 7.0

10

10

15

20

20

25

7.1 - 12.0

15

15

20

25

25

-

12.1 - 20.0

20

20

25

-

-

-

230

0 - 2.0

6

6

6

6

6

6

2.1 - 3.4

6

6

6

6

6

6

3.5 - 5.0

6

6

6

6

10

15

5.1 - 7.0

10

10

10

10

15

15

7.1 - 12.0

15

15

15

15

20

20

12.1 - 20.0

20

20

20

20

25

-

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

Bench mounting (fig. A)

Mounting holes (8) have been provided to facilitate

bench mounting.

Removing and fitting a cutting blade (fig. B & C)

• With the arm in the rest position, use the lip (11)

to slide the guard (4) back. Leave the guard

retracted (fig. B).

• Press and hold down the spindle lock (5) (fig. C).

• Rotate the cutting blade until it locks.

• Rotate the bolt cover (12) out of the way (fig. B).

• Using the Allen key (10), remove the bolt (13) by

turning counterclockwise and then remove the

lock washer (14), the flat washer (15) and the

retaining flange (16) (fig. C).

• Replace the cutting blade (17). Make sure that the

new blade is placed correctly onto the flange (18).

• Secure the blade with the retaining flange (16),

the flat washer (15) and lock washer (14) and the

bolt (13).

• Move the guard back down and release the

spindle lock (5).

Summary of Contents for MTS24

Page 1: ...MTS24 ...

Page 3: ...B 4 8 10 6 5 7 9 2 3 1 4 12 11 A C 4 16 15 14 13 5 18 17 ...

Page 4: ...21 22 19 6 9 7 28 20 23 24 25 27 D E F ...

Page 5: ...31 29 26 30 34 33 32 26 35 7 41 35 30 38 29 38 37 28 7 G H ...

Page 6: ...36 39 40 I J K 3 36 4 9 ...

Page 7: ...L 31 7 42 M N ...

Page 98: ......

Page 99: ......