MAINTENANCE

MAINTENANCE

• To ensure the efficiency of the product it is imperative that competent, professional personnel carry out maintenance within the time li-

mits established by the installer, the manufacturer and the legislation in force.

• Maintenance activities, repairs and replacement of parts must be duly documented. The documentation must be kept by the user so that

it is available for the relevant competent personnel.

• Always disconnect the equipment from the power supply by means of the main switch or by removing the plug before performing main-

tenance or cleaning.

• If the power is ON for operation checks, check or disable all control devices (radio controls, push-button panels etc.) with the exception

of the device used by the maintenance engineer.

•

Automatic gate systems with mechanical parts should be inspected frequently, to check for imbalances or signs of mechanical damage to the supports

and the harness.

NOTE:

Compliance with Machinery Directive 2006/42 EC: when you have installed the equipment, you must complete a Declaration of Con-

formity and a Scheduled Maintenance Plan and then hand over copies of these documents to the user.

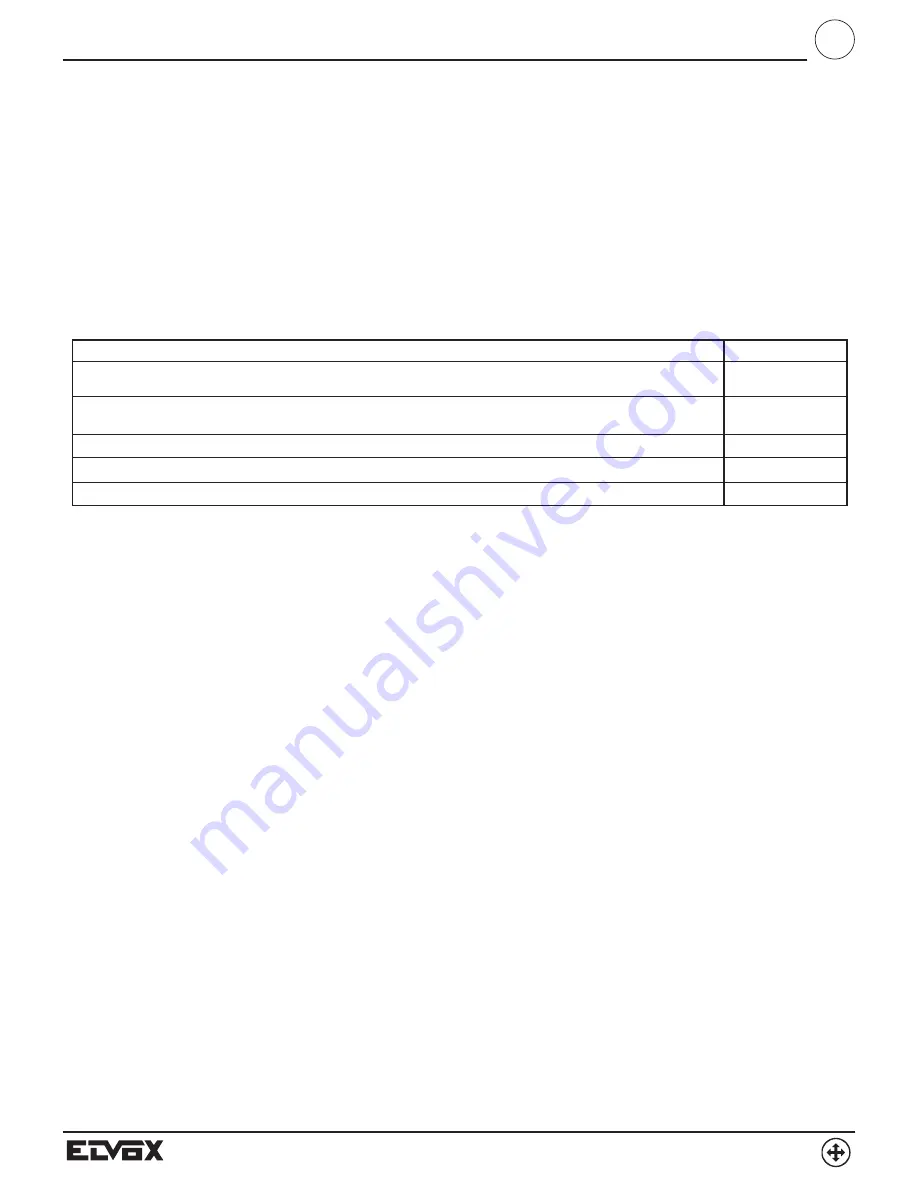

SCHEDULED MAINTENANCE

The maintenance operations recommended for the electrical system are as follows:

Operation

Average frequency

Check the efficiency of the detection and anti-crushing devices (photocells, detector, safety edges) and of the

controls.

6 months

Check the efficiency of the electrical system and test the efficiency of the automatic differential overload switch

protecting the electrical system.

6 months

Check the inside of the electronic equipment housing and clean out any insects, dirt or dampness.

6 months

Check the efficiency of the remote control batteries. Change spent batteries.

6 months

Remove obstacles such as branches or bushes which might be permanently blocking the photocell beam.

6 months

GB

23/36

Routine maintenance

All the following operations must be performed when necessary, and at least once a year.

Gate:

Lubricate (with an oiler) the gate runner wheels and the top runner rails. Make sure the rack is securely fastened, clean and free from build-

up. Clean the runner track.

Automation system:

Make sure the safety devices (photocells, safety edge strips, etc...) are working properly.

No special maintenance is envisaged for this system.

However, if intervention is necessary for mechanical parts, always remove the actuator to enable repairs by authorised personnel.

If the power supply cable is damaged, it must be replaced by the manufacturer or its technical assistance service, or in any case by an in-

dividual with similar qualifications, so as to avoid all risks.

DISMANTLING - DISPOSAL

If the decision is taken to decommission the actuator or the entire automatic closure system, it should be removed and recycled in accor-

dance with the relevant standards.

INFORMATION FOR THE USER

- Carefully read all enclosed instructions and documentation.

- This product must be used exclusively as specified in design, any other use is to be considered improper and therefore hazardous.

- The information in this document and any attached paperwork may be subject to modification without notice. It is supplied as a guide-

line for product application.

- In the event of a fault and/or poor operation of the automatic gate system, disconnect the installation from the mains by means of the

main switch and contact professionally qualified personnel or an authorised service centre for assistance. Never attempt direct repairs

or intervention.

- Have the general operation of the automatic gate system and the safety devices checked once a year by qualified personnel.

- In the event of a mains power failure, manually release the motor.

SAFETY PRECAUTIONS

1. Do not enter the automatic gate system's range of movement while it is in motion; wait until all movement has stopped.

2. Only activate the automatic gate system when it is completely visible and free from any obstacles.

3. Do not allow children or animals to play or sit near the range of movement. Do not allow children to play with the opening controls, or

with the radio control.

4. Do not attempt to counteract automatic gate system movement as this result in a dangerous situation.

5. Do not touch the equipment with wet hands and/or feet.