Heating and cooling systems use water as a medium for heat transfer. The water circulates from where the

warm water is generated to the user and back. Even if the system always re-uses the same water, lime and

aggressive materials enter the closed water system when first filling the system, which can damage modern

components.

The filling apparatus filters lime and aggressive dissolved substances such as sulfate, nitrate and chloride out

of the fill-up water. The device operates on the basis of a mixed bed ion exchanger and provides demi-

neralised water that has been completely desalinated. Thus, damage caused by lime and corrosion can be

effectively prevented in the heating system.

The filling apparatus is equipped with precise meters for monitoring pure water production in terms of qua-

lity and quantity.

This method does not release any chemical additives into the water.

The device operates without an external power supply.

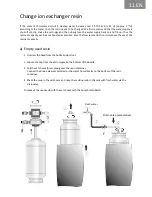

If the ion exchange capacity is exhausted, then the ion exchange resin can be easily replaced and disposed of

with the household waste.

Protective

measures:

Only trained personnel should use the filling apparatus.

Operating specifications must be adhered to according to this manual.

Local guidelines are to be followed for the connection between sanitary and heating sys-

tems. The device already has a returnvalve. In the DIN EN 1717 (Germany) field of

application, a pipe disconnector must also be installed before the fill-up station.

The system is not suitable for unmonitored, permanent connection under pressure. The

valves in the input and output are to be kept closed and only to be opened for the dura-

tion of the system filling.

Even demineralised water contains dissolved gasses, including oxygen and carbon diox-

ide that can cause the beginning of a corrosion process. The gases are purged by heating

the water, therefore we recommend carrying out a heating test run for the system as

soon as possible after fill-up.

The function

According to the latest standards

Leading boiler manufacturers and component suppliers approve and recommend the procedure for purging

make-up water via the ion exchanger.

The demineralised make-up water as a result of desalination also fulfills the requirements for heater fill-up

water quality according to VDI guideline 2035 (Association of German Engineers), the SWKI guideline

BT 102-01 (Swiss Heating and Air Conditioning Engineers) and the Ö-Norm H5195.

6 EN