56

6.3.16 MAINTAINING THE HYDROSTATIC TRANSMISSION

Machines AJ102, AJ110 and AG122:

To ensure reliable operation of the transmission, you must maintain the proper oil level. The transmission

filling ports are accessible after removal of the machine’s removal tube (

6.3.10

). The prescribed

values are shown in the following chart.

Transmission type

Oil type

Oil level

TUFF-TORQ K46

SAE 10W-30, API CD

at least half the height of the distribution reservoir

TUFF-TORQ K62

SAE 10W-30, API CD

lines 5-7 on the distribution reservoir

TUFF-TORQ K664, KXH 10

SAE 5W-50, API CD

Between the turns on the filling screw

Machines AJ102 4x4:

To ensure reliable operation of the transmission, you must maintain the proper oil level. The transmission

filling port is under the seat of the mower (

3.4.5

). The prescribed values are shown in the following

chart.

Transmission type

Oil type

Oil level

TUFF-TORQ K 664

SAE 5W-50, API SG

synthetic oil

according to the level marks in the expansion

tank (

3.4.5

).

KANZAKI KXH 10 N

SAE 5W-50, API SG

synthetic oil

according to the level marks in the expansion

tank (

3.4.5

).

If there are problems with the transmission, get immediate help from an authorized service

centre to prevent serious damage.

6.3.17 OVERVIEW OF BOLT TORQUE

Mowing mechanism:

Torque

Central blade bolt

30 ± 3 Nm

M12 nuts for the mowing mechanism drive pulleys

45 - 55 Nm

10x25 KL 100 RIPP bolt for the shoulder of the tensioning pulley of the mowing

mechanism drive belt

55 - 65 Nm

Steering:

M8x30 bolt to the steering section

15 - 25 Nm

M12 bolt to the steering section

35 - 45 Nm

Engine:

Bolt to the electromagnetic connector

60 - 70 Nm

Bracket screw for the drive belt tension pulley

25 - 35 Nm

Self-locking nuts must be replaced with new ones during removal and reinstallation.

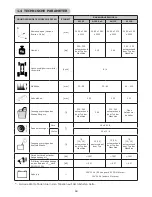

6.4 LUBRICATION

Lubricate the machine according to the following schedule.

The bearings of the tensioning pulleys, guide pulleys and mowing mechanism are self-lubricating.

Before storing the machine for an extended time, thoroughly lubricate all areas shown in the schedule.

But particularly the half-axles of the front and rear axles

(it is necessary to disassemble the rear

wheels).

Summary of Contents for EF106J Starjet

Page 2: ...2 1 2 1 3 1 1 3 2a ...

Page 3: ...3 1 3 2b 1 3 2c 1 3 2d ...

Page 4: ...4 3 1 3 3 1a 3 3 1b ...

Page 5: ...5 3 3 1c 3 3 1d 3 3 2a ...

Page 6: ...6 3 3 2b 3 3 2c 3 3 2d ...

Page 7: ...7 3 3 2e 3 3 2f 3 3 2g ...

Page 8: ...8 3 3 2h 3 3 2i ...

Page 9: ...9 3 3 2j 3 3 2k ...

Page 10: ...10 3 3 2l 3 3 2m 3 3 2n ...

Page 11: ...11 3 3 2o 3 4 5 ...

Page 12: ...12 3 4 6 4 1a ...

Page 13: ...13 4 1b 4 2 1a ...

Page 14: ...14 4 2 1b 5 6a 5 6b 6 2 2 ...

Page 15: ...15 6 3 3a 6 3 3b 6 3 6a 6 3 6b 6 3 7a ...

Page 16: ...16 6 3 7b 6 3 7c 6 3 7d ...

Page 17: ...17 6 3 7e 6 3 8 6 3 9a 6 3 9b ...

Page 18: ...18 6 3 9c 6 3 10a 6 3 10b 6 3 10c ...

Page 19: ...19 6 3 10d 6 3 10e 6 3 10f 6 3 11 ...

Page 20: ...20 6 3 12a 6 3 12b 6 3 14 ...

Page 21: ...21 6 4 ...

Page 341: ...341 ...

Page 342: ...342 ...

Page 343: ...343 ...