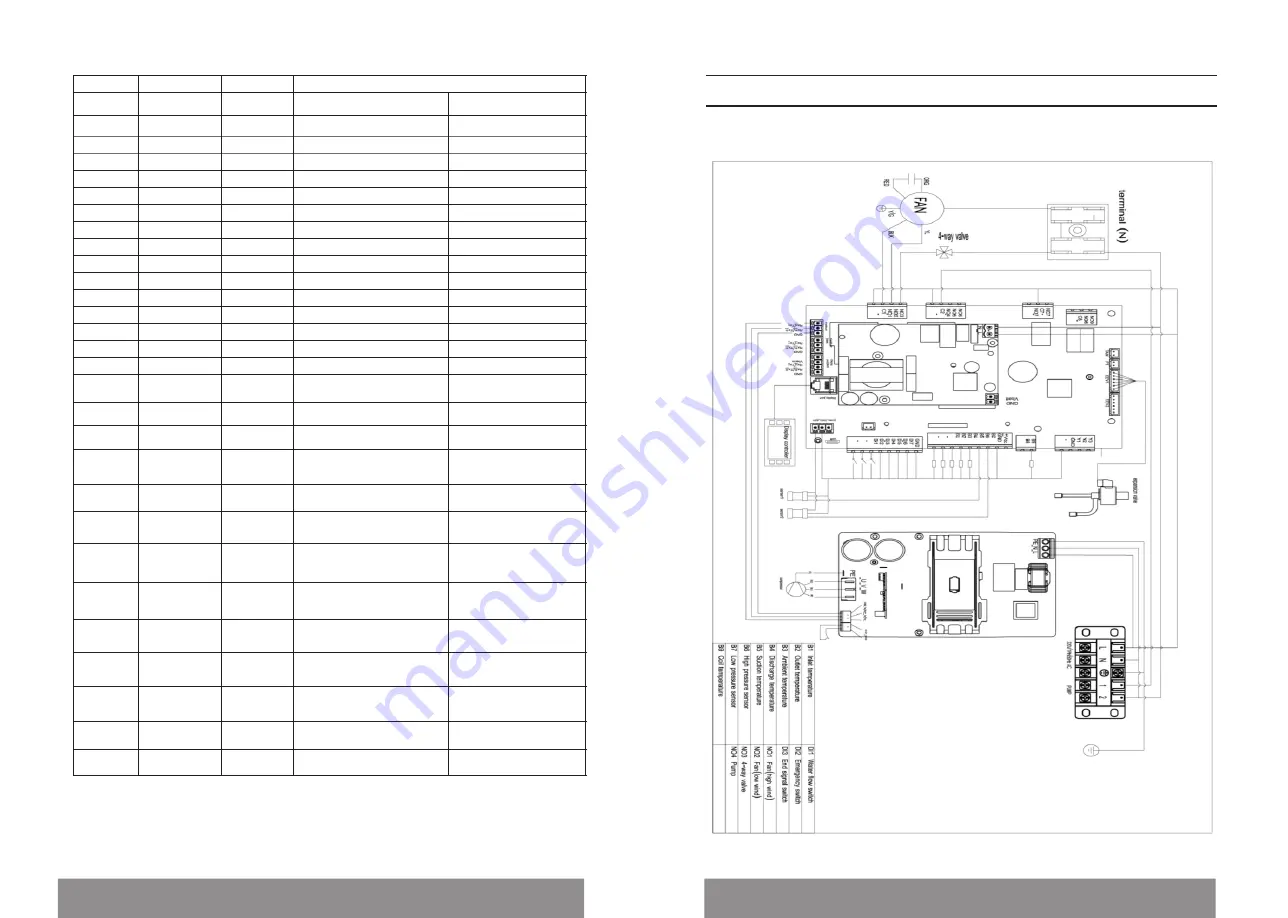

7. DIAGRAMS

7.1 Wiring Diagram

Alarm Code

Description

Possible Cause

Solution

AL79

Power+ alarm:

Safety

inter vention

AL114

Power+ alarm:

Drive connection alarm

Check the wiring connection between

Power Drive and controller

AL115

EEV alarm:

Superheat of EEV is too low

Contact your technical support

AL116

EEV alarm:

EEV LOP alarm

Contact your technical support

AL117

EEV alarm:

EEV MOP alarm

Contact your technical support

AL118

EEV alarm:

High condenser temp. alarm for EEV

Contact your technical support

AL119

EEV alarm:

Low suction temp. alarm for EEV

Contact your technical support

AL120

EEV alarm:

Motor of EEV alarm

Contact your technical support

AL12

1

EEV alarm:

PID of EEV alarm

Contact your technical support

AL122

EEV alarm:

EEV Emergency stop alarm

Contact your technical support

AL123

EEV alarm:

EEV temp. different protection

Contact your technical support

AL12

4

EEV alarm:

EEV pressure different protection

Contact your technical support

AL12

5

EEV alarm:

EEV range error

Contact your technical support

AL126

EEV alarm:

EEV position error

Contact your technical support

AL127

EEV alarm:

EEV serial No. error

Contact your technical support

AL128

Low press alarm

Low pressure protection

Check refrigerant is enough or not

AL129

High press alarm

High pressure protection

Check water volume is enough or not,

check water or air temp. is high or not

AL130

Disc.temp.probe error

Discharge temp. sensor fail or loose

connection

Check discharge temp. check the wire

connection or replace a new sensor

AL131

Suct.temp.probe error

Suction temp. sensor fail or loose

connection

Check suction temp. check the wire

connection or replace a new sensor

AL132

Disc.press.probe error

Discharge pressure sensor fail

Check the running pressure, increase

the water volume or decrease the

setting temp.

AL133

Suct.press.probe error

Discharge pressure sensor fail

Check the running pressure, the

refrigerant is enough or not.

AL134

Tank temp.probe error

Water tank temp. sensor fail or

loose connection

Check water tank temp. check the

wire connection or replace a new

sensor

AL135

EVI SuctT.probe error

EVI suction temp. sensor alarm

Check EVI suction temp. check the

wire connection or replace a new

sensor

AL136

EVI SuctP.probe error

EVI suction pressure sensor alarm

Check EVI suction pressure, check

the wire connection or replace a new

sensor

AL137

Flow switch alarm

Water flow sensor fail or loose

connection

Check the water flow volume is big

enough or not, check flow switch

sensor wire connection

High temp. alarm

Water outlet temp. is too high

Check the water flow volume is big

enough or not, decrease the setting

temp.

AL139

Low temp. alarm

Water outlet temp. is too low

Check the water flow volume is big

enough or not, increase the setting

temp.

AL140

Temp.delta alarm

Temp. different is too much

between water inlet and outlet

Check the water flow volume is big

enough or not

AL152

Power freq.alarm

Frequency of power supply is

unstable

Stop and check the power supply

P35 ALARM CODE LIST

DIAGRAMS P36