Summary of Contents for PDRCF1150029

Page 8: ...Emax Air Dryer REFRIGERATED TYPE COMPRESSED AIR DRYERS Technical Specifications Diagram ...

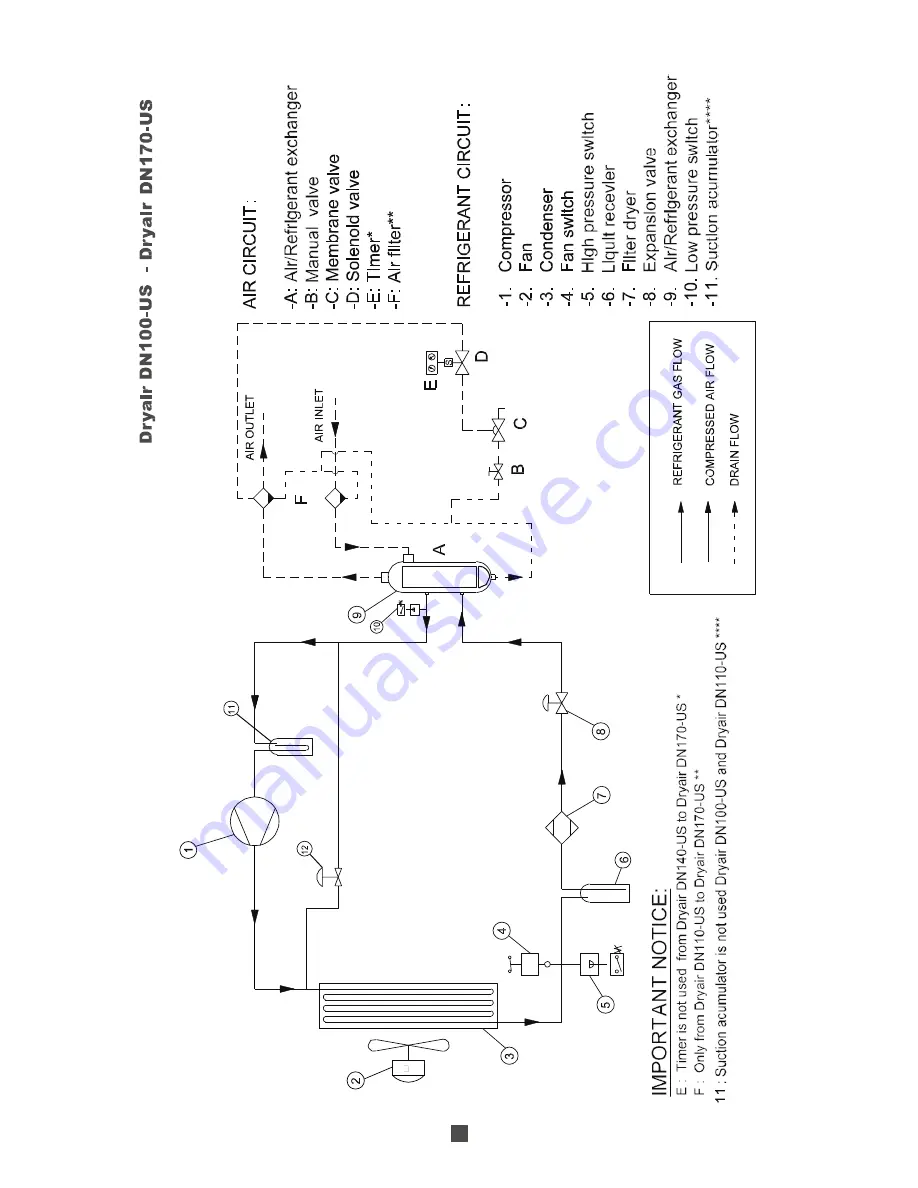

Page 11: ...9 ...

Page 12: ...10 5 2 ELECTRICAL DIAGRAMS Dryair DN10 US Dryair DN30 US ElectricalCircuit ...

Page 13: ...12 Dryair DN40 US Dryair DN80 US Electrical Circuit ...

Page 14: ...15 Dryair DN100 US Dryair DN110 US ElectricalCircuit ...

Page 15: ...16 Dryair DN140 US Dryair DN170 US Electrical Power Circuit ...

Page 18: ...19 Dryair DN10 US Dryair DN30 US 8 ED and ID DRAWINGS ...

Page 19: ...20 Dryair DN40 US Dryair DN60 US ...

Page 20: ...21 Dryair DN70 US Dryair DN90 US ...

Page 21: ...22 Dryair DN100 US Dryair DN110 US ...

Page 22: ...23 Dryair DN140 US Dryair DN150 US ...

Page 23: ...24 Dryair DN160 US Dryair DN170 US ...

Page 24: ...25 Dryair DN30 US ...

Page 25: ...26 Dryair DN50 US ...

Page 26: ...27 Dryair DN70 US ...

Page 27: ...28 Dryair DN80 US ...

Page 28: ...29 Dryair DN110 US ...

Page 29: ...30 Dryair DN140 US ...

Page 30: ...31 Dryair DN160 US ...

Page 31: ...32 Dryair DN170 US ...

Page 32: ...60 9 COMPONENTS LOCATION ...