20

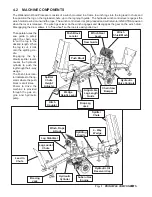

4.3 MACHINE

BREAK-IN

Although there are no operational restrictions on the

Wood Processor when used for the first time, it is

recommended that the following mechanical items

be checked:

A.

After operating for 1 to 5 hours:

1. Check all nuts, bolts and other fasteners.

Tighten to their specified torque.

2. Check hydraulic system for leaks. Tighten

all leaking fittings and replace any leaking

components.

3. Check machine fluid levels: Fuel, engine

oil, and hydraulic oil reservoir. Top up as

required.

4. Check condition of winch.

5. Check the condition of the rope. Replace

if cut, knotted, worn or if it has any broken

strands.

6. Check for entangled material. Remove all

entangled material before resuming work.

7. Lubricate all grease fittings.

B.

After operating for 20 hours:

1. Repeat steps 1 through 7 listed above.

(Section

A)

2. Change engine oil after 20 hours.

3. Go to the normal servicing and mainte-

nance schedule as defined in the Mainte

-

nance Section.

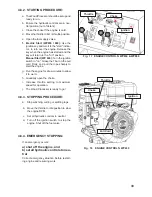

4.4 PRE-OPERATION CHECKLIST

Efficient and safe operation of the Wallenstein Wood

Processor requires that each operator reads and

understands the using procedures and all related

safety precautions outlined in this section. A pre-

operation checklist is provided for the operator. It is

important for both the personal safety and maintain-

ing good mechanical condition that this checklist is

followed.

Before operating the Wood Processor and each time

thereafter, the following areas should be checked

off:

1. Lubricate the machine per the schedule outline

in the Maintenance Section.

2. Check for entangled material. Remove any

twine, wire, chips or other material that has

become entangled.

3. Check the condition of the winch rope. Replace

cut, knotted, worn or if it has any broken strands.

Replace rope if damaged.

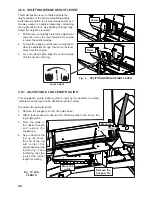

4. Check the wedge and block. Inspect for dam-

aged or broken components and excessive

wear. Lubricate, repair or replace as required.

5. Check for hydraulic leaks. Tighten fittings or

replace components to stop leaks.

6. Check engine and machine fluid levels. Top up

as required.

7. Check that all bearings turn freely. Replace any

that are rough or seized.

8. Make sure that all guards and shields are in

place, secured and functioning as designed.

9. Check the condition of the winch. It must be in

good condition to operate properly.